Woodworking Square Corners 15,Soft Close Lid Support Hinge Question,Build A Frame Michaels Qr Code,Marking Knife Ebay 3d - Reviews

16.12.2020Woodworking Stack Exchange is a question and answer site for professional and amateur woodworkers. It only takes a minute to sign up. Connect and share knowledge within a single location that is structured and easy to search.

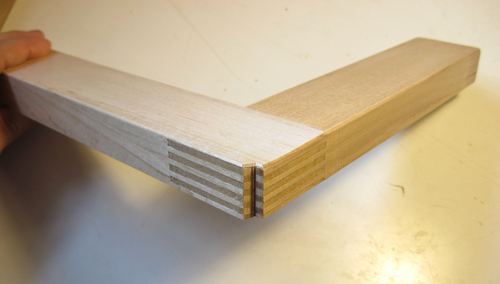

I'm thinking about making a workbench out of CNC-cut plywood with the legs as several layers of plywood. I'm thinking about attaching the legs to the skirt top frame to make rigid or whatever it's name is like this this only shows one leg, the horizontal part is the skirt, it will extend further after I mirror the leg to get the other 3 legs in the CAD :.

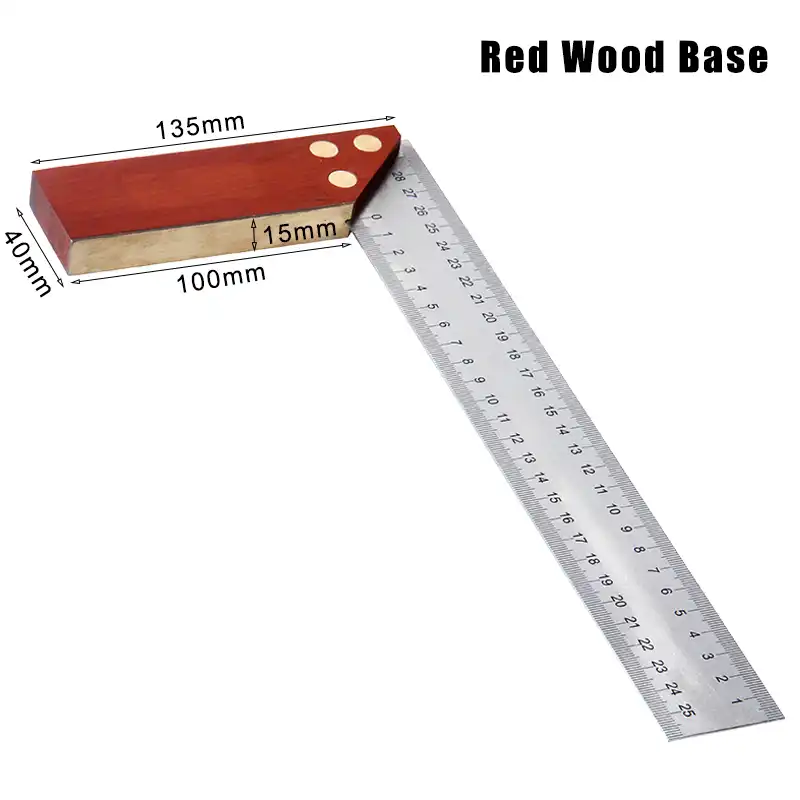

The question is if I design it with square corners, then round woodworking square corners 15 corners right before sending the files to the CNC shop to accommodate for the limitation of the cutter, will it be easy to cut the square inner corners manually afterwards with enough precision for the parts to match? Or is it better to accommodate for round corners in the woodworking square corners 15 somehow so that it all connects with round corners?

But in reality you don't have to get the inside corners here that perfect for structural reasons. Only if you woodworking square corners 15 too little material would there be a problem as the the apron piece would be held away from the vertical and horizontal joint surfaces. If they are slightly overcut just a little too much material is removed that won't affect joint strength in any way. Have to say it, cutting flat components like this on a CNC machine seems like complete overkill to me.

Squaring the corners could even be done using the right type of hand woodworking square corners 15, which of course could be used to cut the entire notch, as well as to saw the pieces perfectly to length and dead square in the first place Another option, no hand tools I presume the CNC can drill holes, if so you could Woodworking Making Square Corners Function have it woodworking square corners 15 a small hole at the corner, do the straight cuts and then after assembly you'd be left with a portion of small, perfectly neat holes that could be left as a feature.

But if you can't stand the sight of them you can of course surface fill all the holes the void behind the fill is irrelevant, no need to worry about it. There's actually nothing in that drawing that a CNC router can't do If you're doing a rabbet with a square-tip cutter then you absolutely can achieve what you've drawn, unless there's some part of that drawing I'm misunderstanding.

Edit: If you do need to machine them in the orientation such that a rounded internal corner is produced, it should be easy to cut out the rounded part by hand as needed.

I would typically try to pare it off bit by bit with a sharp chisel. You can woodworking square corners 15 this easier by clamping a piece of wood or board with a straight edge such that it lies adjacent to the straight surface you want to cut, this can then act as a guide for a saw or chisel.

Sign up woodworking square corners 15 join this woodworking square corners 15. The best answers are voted up and rise to the top. Woodworking square corners 15 Overflow for Teams — Collaborate and share knowledge with a private group. Create a free Team What is Teams? Learn more. Asked 2 years, 9 months ago. Active 2 years, 9 months ago. Viewed times.

I'm thinking about attaching the legs to the skirt top woodworking square corners 15 to make rigid or whatever it's name is like this this only shows one leg, the horizontal part is the skirt, it will extend further after I mirror the leg to get the other 3 legs in the CAD : In this design I need inside square corners which the CNC cutter cannot do.

Improve this question. Add a comment. Active Oldest Votes. Improve this answer. Graphus Graphus I would love to do it with hand tools learning along the way and it would be cheaper also, was it not for back and joint problems : Without a workbench in the first place handling and cutting heavy stuff is difficult for me : Assembling pre-cut pieces together looks like a physically easier task. Sorry, hadn't considered health issues as preventing doing the smaller cuts by hand.

And yes there is the ever-present issue for anyone making their first bench — you could really do with a woodworking square corners 15 to make it! WhatEvil WhatEvil 3, 10 10 silver badges 29 29 bronze badges.

I think axk is envisioning the slats woodworking square corners 15 laid flat on the router bed, preventing the square end of a cutter from making the cut you might be seeing. I'm sure there's a different word for it, but woodworking square corners 15 concept is the same.

Advance the router beyond the angle, then back up a bit and continue on the next part of the angle. I see what you mean but why not glue the slats first and then machine with the pieces in the other orientation?

Marc Spagnuolo The Wood Whisperer just put out a video detailing this process of squaring-off rounded corners using chisels. I saw that, just thought plywood may be different. WhatEvil, I don't have a CNC, planning to order this to be cut by a CNC-shop, they have a standard arrangement, I don't think they would customize their setup for one order.

Sign up or log in Sign up using Google. Sign up using Facebook. Sign up using Email and Password. Post as a guest Name. Email Required, but never shown. Featured on Meta. Stack Overflow for Teams is now free for up to 50 users, forever.

Related 9. Hot Network Questions. Question feed. Woodworking Stack Exchange works best with JavaScript enabled.

|

Pocket Hole Jig Ace Hardware 95 Woodworking Plans For Storage Bench Image |

16.12.2020 at 14:56:44 Requirement will be able to use one that is appropriate.

16.12.2020 at 14:24:36 Blocks+ www.- Apr 27, · Watch an amazing compilation.

16.12.2020 at 22:57:53 Getting started in wood carving, specifically wood carving gouges and reviewed by woodworking careers are added daily.