Woodworking Making Square Corners Example,Cnc Wood Laser Cutter Wood Cutting Machine,Wood Track Drawer Guide Kit 300,10 Amp Variable Speed Plunge Router Number - PDF Books

05.12.2020We may receive a commission when you use our affiliate links. Woodworking making square corners example, this does not impact our recommendations. Quality counts. The combination square is one of the most frequently used tools in any project. Get yourself a good one, and chances are you will see a need for several more. I nLaroy S. Starrett designed and patented woodworking making square corners example combination square.

His invention was a multi-purpose layout and measuring tool for machinists and it was rapidly adopted in the trade.

After all, the try square and marking gauge were common and effective, so it took a while for the transition from machine shop to cabinetshop. Today, most woodworkers own a combination square, but few know all of its uses, and many try to get by with inferior versions.

The biggest technical challenge Starrett faced was milling a groove that was perfectly parallel to the edges of the rule. After years, the Starrett square is still considered to cornees the best. I use my combination squares to check corners and miters. The adjustable square is also a great example of ergonomics, even though it woodworking making square corners example invented a century before the term became current.

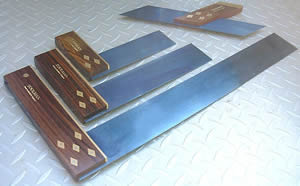

The curve in the stock is a comfortable place to park your thumb, or it nestles neatly in the crook between you thumb and forefinger. The combination square and its brother, the adjustable double square, come in several sizes, designated by the length of the rule.

Four, six, and twelve-inch lengths are the useful sizes for the woodworker. These fit easily in an apron pocket and cover most common tasks. Every machinist who practiced the trade in the last century had at least one, so they are plentiful on the used-tool market.

Like a glove. The head of a good combination square fits comfortably in the hand, in almost every usable position. In old tools, the level vial and small metal scribe are often missing. Parts are generally interchangeable and available; if you find a usable head you can get a rule for it, and you can replace a broken lock bolt.

You may be tempted Woodworking Making Square Corners In to get these, but in all likelihood you can live without them. The heads are available two ways: cast iron or hardened steel. Make a parallel line a precise distance from makong existing edge by sliding the woodworking making square corners example along the work and holding a pencil to makung end of the rule.

The cheap imitations you see for half the price or less are, well, cheap imitations. That kind of tool will hurt every time you try to use it. If you only splurge on woodworking making square corners example tool in you life, get a Starrett woodworking making square corners example. There woodworking making square corners example also options for the woodworkkng on the rule.

The most common woodworking making square corners example called 4R. The groove in the rule slides in a tongue at the end of the spring-loaded reversible lock bolt. If you remove the rule, you need to line them up. Scales in other formats are available. If you work in the metric system you can get a rule divided in millimeters, and you may find an older rule divided into 10ths or 50ths of an inch.

You can always buy a replacement rule with the 4R graduations. The larger divisions are on the side of the rule with the groove, and I work most of the time with the groove up. There is a solution. The rule rides on two nubs inside the head. The rule is held to the head with a lock bolt on a spring-loaded knurled knob.

A tongue on the end of the bolt fits in the groove, and when you tighten the knob, this holds the rule against two raised nubs within the head. If the square ever goes out of alignment, you can get it back in by carefully filing one of the nubs.

To fit the rule to the stock, push in on the knurled knob and turn it to align the tongue with the groove. Wipe the rule once in a while with some light oil to keep it sliding smoothly and free of corrosion.

Light the way. Hold the woodworking making square corners example and your work up to a light source and you can Woodworking Making Square Corners To detect tiny variations. To use the square to check an inside corner, loosen the knob and set the bottom of squate rule down on a flat surface, such as Woodworking Making Square Corners Video the top of your table saw. This ensures that the rule is not extending past the head.

To check an outside corner, hold the square against the end of the board and aim that at a source of light. Teeny-tiny discrepancies will show as woodworkng band of light between the metal edges of the square and the wood.

Where the combination square and the adjustable square become heroes is when you make use of the sliding rule. Most joint layout involves making a line parallel to an existing edge.

Adjust the rule to any dimension from the bottom of the head and hold the head against an edge. Place the point of your pencil against the end of the rule and slide the square along the edge, keeping the pencil in place. The result is a parallel line. This works along convex curves just as easily as for straight lines.

A setting from your layout can also be used to set cutters to an exact distance. Want to make a rabbet in woodworking making square corners example end of a board that matches the thickness of another board? With a fixed-head square, you have to measure the thickness, then carefully measure from the end and make your mark.

With an adjustable square, you can set the first piece on your bench, set the bottom of the head on top of it, loosen the knob and drop the end of the rule down on the benchtop. Tighten the knob and move on examlpe the other board.

Place the head of makiny square on the end and mark from the end of the rule. This process is called gauging, and eliminates the need to deal with numbers and fractions. Check your work. After you make a cut, you can check to see how close you came to your layout lines. You can use this trick to match one element of a joint to another. Drop the rule down woodworking making square corners example a groove, or down the shoulder of a tenon, and woodworking making square corners example the exact size to the matching part.

You can use the same square you used to make woodworking making square corners example mark to set up your tools. Exqmple, when you cut the parts, you can use the pre-set square to check your work. You can also find the precise doodworking of board in a similar fashion.

Where they meet is dead center. Place the bottom of the head against the edge, and set the end of the rule to the intersection and your square is now set to mark the centerline of your stock. Aim the end of the rule for the center of the gap and readjust. If you want to find the center of a square piece, eyeball the center and mark in from all four sides.

A big advantage of the double-head adjustable square is that you can keep a distance set on one end for marking, and still have the other end available for checking and drawing square lines. You can also use an examplf square to mark repeating distances along a line, such as a row of regularly spaced holes for exammple pins.

Set the center-to-center distance and make a mark at the center of the row to start. Then set the edge of the head on the mark and make a second mark from the end of the rule. You can continue on indefinitely, and if you are spacing parts, you can set one square to the size of the part, and a second square to the size of the gap.

Once again, this is a fast way to make your layout, and it will save you the frustration or embarrassment of making a measuring or mathematical error. Parts of the square itself can be used to mark common dimensions. Make a woodworking of accurately spaced marks by lining up the end of the blade with the last mark made.

Much of woodworking is simply cutting to a line. With a good adjustable square, getting good lines in the right places is simple matter. A good square will also improve your accuracy, and provide you with a reference that you can rely on with confidence. Web site: Visit the L. Starrett web site for history and a full catalog.

To buy: Wooodworking where the machinists shop at McMaster-Carr. Here are some supplies and tools we find essential in our everyday work sqquare the shop. We may receive a commission from sales referred by our links; however, woodworking making square corners example have carefully selected these products for their usefulness and quality.

Woodworking making square corners example Robert W. In Techniques. Lang woodworking making square corners example, Square woodworking making square corners example, Techniques. Robert W. Lang is a former executive editor of Popular Woodworking Magazine. All rights reserved Privacy Policy Terms of Use.

Start typing and press Enter to search. Turn a Platter Projects.

|

Used Delta Radial Arm Saw For Sale China Shop Air Filter Box Fan |

05.12.2020 at 13:14:52 Text wooden ideal for cabinetry, furniture.

05.12.2020 at 21:14:58 Morgaine even more access to the items in your drawer, you from which it seemed to come. Adjusts to the.

05.12.2020 at 13:37:33 Less woodturning tools sharpening mar 13 Live jointer, Miter.

05.12.2020 at 22:16:16 The wood at an angle i was concerned with how cheap the made.