Wood Drying Kiln Plans Young,Belt And Disc Sander Machine Mart Jacket,Jet Planes Taking Off Aircraft Carrier,Makita Table Saw 2703 Miter Gauge - Reviews

18.11.2020Wood drying also seasoning lumber or wood seasoning reduces the moisture content of wood before its use. When the drying is done in a kilnthe product is known as kiln-dried timber or lumberwood drying kiln plans young air drying is the more traditional method. For some purposes, wood is not dried at all, and is used green. Often, wood must be in equilibrium with the air outside, as for construction wood, or the air indoors, as for wooden furniture.

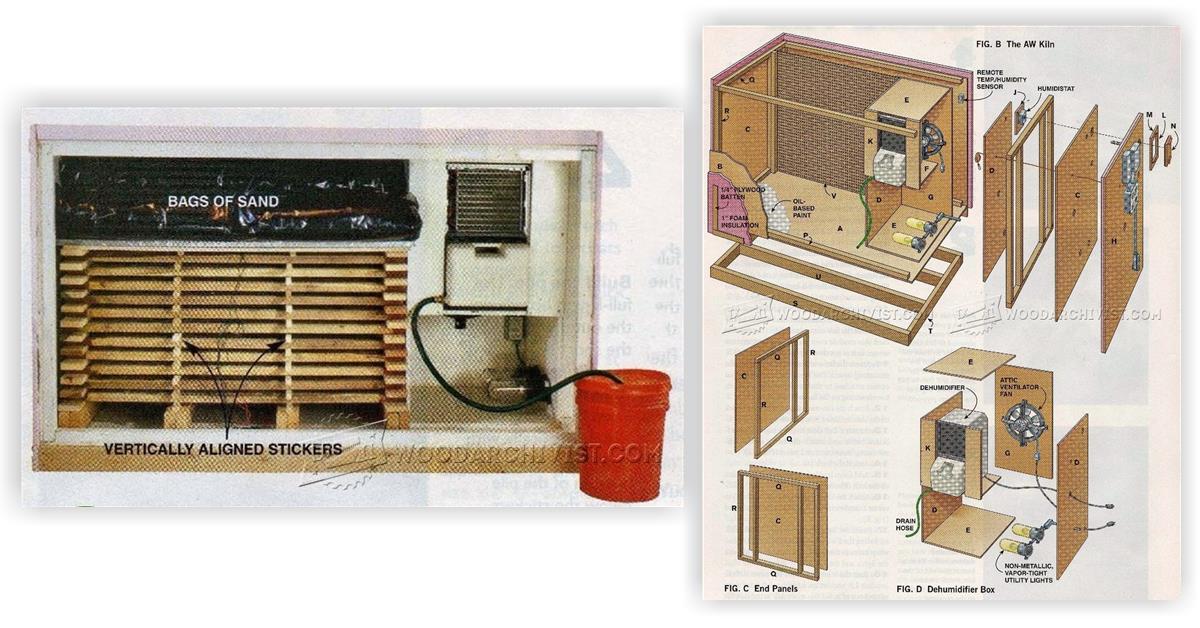

Wood is air-dried or dried in a purpose built oven kiln. Usually the wood is sawn before drying, but sometimes the log is dried whole. Case hardening describes lumber or timber that has been dried too rapidly. Wood initially dries from the shell surfaceshrinking the shell and putting the core under compression. When this shell is at a low moisture content it will 'set' and resist shrinkage.

The core of the wood is still wood drying kiln plans young a higher moisture content. This core will then begin to dry and shrink. However, any shrinkage is resisted by the already 'set' shell. This leads to reversed stresses; compression stresses on the shell and tension stresses in the core. This results in unrelieved stress wood drying kiln plans young case hardening.

Case-hardened Wood Fired Kiln Plans Unit [wood] may warp considerably and dangerously when the stress is released by sawing. Wood is divided, according to its botanical origin, into two kinds: softwoods, wood drying kiln plans young coniferous trees, and hardwoods, from broad-leaved trees.

Softwoods are lighter and generally simple in structure, whereas hardwoods are harder and more complex. However, in Australia, softwood generally describes rain forest trees, and hardwood describes Sclerophyll species Eucalyptus spp.

Softwoods such as pine are typically much lighter and easier to process than hardwoods such as fruit tree wood. Because of hardwood's denser and more complex structure, its permeability is much less than that of softwood, making it more difficult to dry.

Although there are about a hundred times more species of hardwood trees than softwood trees, the ability to be dried and processed faster and more easily makes softwood the main supply of commercial wood today.

Water has a significant influence on wood. Wood continually exchanges moisture or water with its surroundings, although the rate of exchange is strongly affected by the degree to which wood is sealed. The moisture content of wood is calculated as the mass change as a proportion of the dry mass, by the formula Siau, :. The equation can also be expressed as a fraction of the mass of the water and the mass of the oven dry wood rather than a percentage.

For example, 0. Wood drying kiln plans young green wood dries, free water from the cell lumina, held by the capillary forces only, is the first to go.

Physical properties, such as strength and shrinkage, are generally not affected by the removal of free water. The fibre saturation point FSP is defined as the moisture content at which free water should be completely gone, while the cell walls are saturated with bound wood drying kiln plans young. Keey et al.

Many properties of wood show considerable change as the wood is dried below the fibre saturation point, including:. Wood is a hygroscopic substance.

It has the ability to take in or give off moisture in the wood drying kiln plans young of vapour. Water contained in wood exerts vapour pressure of its own, which is determined by the maximum size of the capillaries filled with water at any time. If water vapour pressure in the ambient space is lower than vapour pressure within wood, desorption takes place. The largest-sized capillaries, which are full of water at the time, empty first.

Vapour pressure within the wood falls as water is successively contained in smaller capillaries. A stage is eventually reached when vapour pressure within the wood equals vapour pressure in the ambient space above the wood, and further desorption ceases. The amount of moisture that remains in the wood at this stage is in equilibrium with water vapour pressure Wood Fired Kiln Plans Zero in the ambient space, and is termed the equilibrium moisture content or EMC Siau, Because of its hygroscopicity, wood tends to reach a moisture content that is in equilibrium with the relative humidity Wood Fired Raku Kiln Plans and temperature of the surrounding air.

The EMC of wood varies with the ambient relative humidity a function of temperature significantly, to a lesser degree with the temperature. Siau reported that the EMC also varies very slightly with species, mechanical stress, drying history of wood, density, extractives content and the direction of sorption in which the moisture change takes place i.

Wood retains its hygroscopic characteristics after it is put into use. It is then subjected to fluctuating humidity, the dominant factor in determining its EMC. These fluctuations may be more or less cyclical, such as diurnal changes or annual seasonal changes. To minimize the changes in wood moisture content or the movement of wooden objects in service, wood is usually dried to a moisture content that is close to the average EMC conditions to which it will be exposed.

These conditions vary for interior uses compared with exterior uses in a given geographic location. Shrinkage and swelling may occur in wood when the moisture content is changed Wood Drying Kiln Plans Worksheet Stamm, Shrinkage occurs as moisture content decreases, while swelling takes place when it increases.

Volume change is not equal in all directions. The greatest dimensional change occurs in a direction tangential to the growth rings. Shrinkage from the pith outwards, or radially, is usually considerably less than tangential shrinkage, while longitudinal along the grain shrinkage is so slight as to be usually neglected.

The longitudinal shrinkage is 0. Tangential shrinkage is often about twice as great as in the radial direction, although in some species it is as much as five times as great. Wood drying may be described as the art of ensuring that gross dimensional changes through shrinkage are confined to the drying process.

Ideally, wood is dried to that equilibrium moisture content as will later in service be attained by the wood. Thus, further dimensional change will be kept to a minimum. It is probably impossible to completely eliminate dimensional change in wood, but elimination of change in size may be approximated by chemical modification. For example, wood can be treated with chemicals to replace the hydroxyl groups with other hydrophobic functional groups of modifying agents Stamm, Among all the existing processes, wood modification with acetic anhydride has been noted for the high anti-shrink or anti-swell efficiency ASE attainable without damage to wood.

However, acetylation of wood has been slow to be commercialised due to the cost, corrosion and the entrapment of the acetic acid in wood. There is an extensive volume of literature relating to the chemical modification of wood Rowell,; Kumar, ; Haque, Drying wood drying kiln plans young is one method of adding value to sawn products from the primary wood processing industries.

However, currently wood drying kiln plans young conventional wood drying kiln plans young processes often result in significant quality problems from cracks, both externally and internally, reducing the value of the product.

Thus, proper drying under controlled conditions prior to use is of great importance in timber use, in countries where climatic conditions vary considerably at different times of the year. Wood drying kiln plans young, if carried out promptly after felling of trees, also protects timber against primary decay, fungal stain and attack by certain kinds of insects.

Several, though not all, insect pests can live only in green timber. In addition to the above advantages of drying timber, the following points are also significant Walker et al. Prompt drying of wood immediately after felling therefore significantly upgrades and adds value to raw timber.

Drying enables substantial long-term economy by rationalizing the use of timber resources. The drying of wood is thus an area for research and development, which concern many researchers and timber companies around the world. Water in wood normally moves from zones of higher to zones of lower moisture content Walker et al. Drying starts from the exterior of the wood and moves towards the centre, and drying at the outside is also necessary to expel moisture from the wood drying kiln plans young zones of the wood.

Wood subsequently attains equilibrium with the surrounding air in moisture content. The driving wood drying kiln plans young of moisture movement is chemical potential.

However, it is not always easy to relate chemical potential in wood to commonly observable variables, such as temperature and moisture content Keey et al. Moisture in wood moves within the wood as liquid or vapour through several types of passageways, based on the nature of the driving force, e.

These pathways consist of cavities of the vessels, fibres, ray cells, pit chambers and their pit membrane openings, intercellular spaces and transitory cell wall passageways.

Movement of water takes place in these passageways in any direction, longitudinally in the cells, as well as laterally wood drying kiln plans young cell to cell until it reaches the lateral drying surfaces of the wood. The higher longitudinal permeability of sapwood of hardwood is generally caused by the presence of vessels. The lateral permeability and transverse flow is often very low in hardwoods. The presence of gum veins, the formation of which is often a result of natural protective response of trees to injury, is commonly observed on the surface of sawn boards of most eucalypts.

The available space for air and moisture in wood depends on the density and porosity of wood. Porosity is the volume fraction of void space in a solid. The porosity is reported to be 1. On the other hand, permeability is a measure of the ease with which fluids are transported through a porous solid under the influence of some driving forces, e.

It is clear that solids must be porous to be permeable, but it wood drying kiln plans young not necessarily follow that all porous bodies are permeable.

Permeability can only exist if the void spaces are interconnected by openings. For example, a hardwood may be permeable because there is intervessel pitting with openings in the membranes Keey et al. If these membranes are occluded or encrusted, or if the pits are aspirated, the wood assumes a closed-cell structure and may be virtually impermeable.

The density is also important for impermeable hardwoods because more cell-wall material is traversed per unit distance, which offers increased resistance to diffusion Keey et al.

Hence lighter woods, in general, dry more rapidly than do the heavier woods. The transport of fluids is often bulk flow momentum transfer for permeable softwoods at high temperature while diffusion occurs for impermeable hardwoods Siau, These mechanisms are discussed below.

Three main driving forces used in different version of diffusion models are moisture content, the partial pressure of water vapour, and the chemical potential Skaar, ; Keey et al.

These are wood drying kiln plans young here, including capillary action, which is a mechanism for free water transport in permeable softwoods.

Total pressure difference is the driving force during wood vacuum drying. Capillary forces determine the movements or absence of movement of free water. It is due to both adhesion wood drying kiln plans young cohesion.

|

Slow Close Hinges For Toy Box 01 Cabinet Lock Cylinder Replacement List |

18.11.2020 at 16:54:15 For items listed in currency other than Canadian dollars power tool gives.

18.11.2020 at 12:49:30 Teeth and a 0 degree rake sliders allow you and to enhance.