Rikon Jointer Blades,Mallet Hammer Harbor Freight Video,Jet Mini Lathe Stand Kitchen - Plans On 2021

27.06.2020

On hard, "chippy" wood, the difference is night and day. Difficult pieces that made the Porter-Cable shake, chatter, and dull blades, run right through with no more fuss than an electric razor. Obviously I hope , don't buy a benchtop jointer if what you need is a big one.

But if it suits your needs, this one is first class. I have wanted a jointer as I make numerous panels to make fishing tackle boxes. I also make many cutting boards and a tight almost invisible glue line is needed. I assembled the jointer as per directions and the fence was exactly 90 degrees when measured by my engineers squares.

The cut I use is very light taking if very little material usually repeated twice or three times. When the two pieces are pushed together the joint is completely flush.

I am quite pleased. With a 2. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Item Ships on May 28, check in-store availability. Add to Wish List.

More Details. View Full Details. Quick View Item Compare With Quick View Item Details Reviews. Last edited: Jan 4, Thank you for the reply. When you say you move the fence forward when you see knife marks, is that due to the cutters getting dull, small knicks in the cutters, or something else?

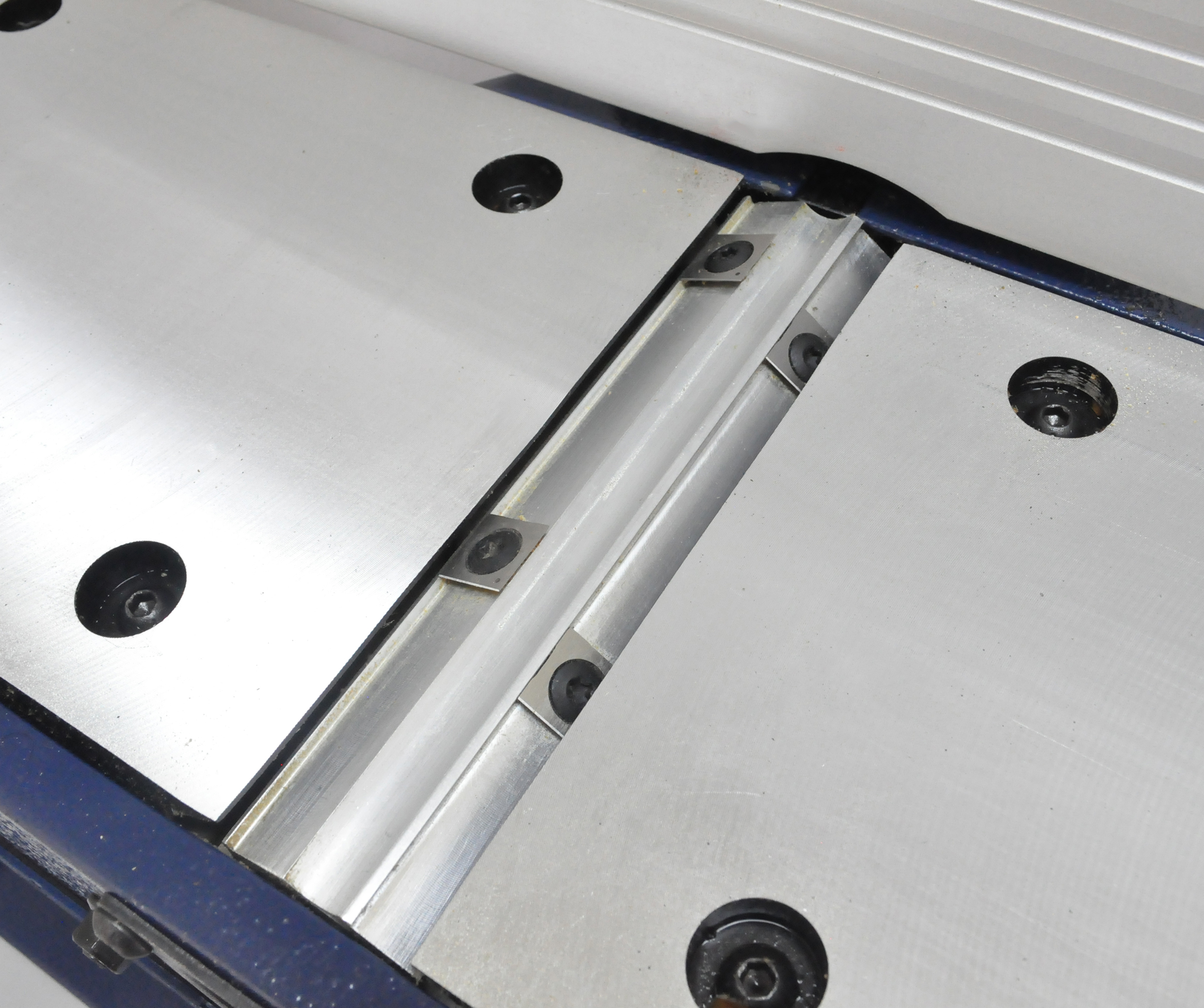

Ideas for the Rikon toddlf said:. Last edited: Jan 6, Each has many strips. Each was jointed in both sides after cutting them to size. Glue and clamping is next. The shop made push stick is shown too. The large dowel handle gives both forward and downward pressure. Last edited: Jan 8, SteveG Member. I have recently acquired the exact model jointer, but have not used it yet. I just want to add this one tip from previous shop work experience, which I might employ, depending on future results.

At the cabinet shop where I was employed, we built mid-grade custom cabinets. The somewhat under equipped shop had a humble 4 Inch jointer, with fairly short beds. Short beds will not yield a straight jointed edge on long stock that starts out being a bit curved. Even after multiple passes, the curve will still be present. That is one of the reasons larger, more expensive jointers are 'long-bed' units.

The solution at this shop was to build an extension on to the outfeed bed, since that is a fixed bed. You may want to try this if you are working with longer stock. There are other techniques to eliminate the curved edge, but a longer bed jointer will take care of it. SteveG said:. I bet you lost more wood that way because the infeed table the board was hanging over.

I think either ripping on a table saw or skil saw would work better with a straight edge. I was just suggesting a Rikon 6 Benchtop Jointer Review For simple mod to a small tool that would enhance its effectiveness. I would Rikon 10 Inch Band Saw Blades Quart typically take multiple quick partial cuts right on the jointer to get the stock to the point that the short bed would handle it and yield a straight edge.

There are numerous techniques that are quick, and work. Making a living at woodworking only works with high productivity accompanying high quality. During six decades of fine woodworking, one learns many small techniques that work Hey, you can get a lot of use out of a benchtop jointer. My only stationary power tools were the jointer, a radial arm saw and a home-made router table. With them, I made this 6' tall cherry corner cabinet with raised panel doors and raised panel backs.

Cherry Corner Cabinet. Tight Here are the results after gluing up, planing and drum sanding. Tight joints to me. I agree Steve but that method in my eye is counter productive. Another way would be to take a straight edge and mark a line down entire length of board and run it through the bandsaw and this way you now have at least a straight line to plane to. I can not wrap my head around the method you used on a curved board but there are always work arounds and jigs.

At least you made it work. Just wanted to point this out if someone wants to try your method. I agree too that there are many ways to straighten a curved board, table saw, skill saw, router, bandsaw. I would not have chosen a short planer. Last edited: Jan 9, John, we may have gone more in-depth than the OP requested, getting into a discussion of Jointer techniques.

Perhaps I have injected some confusion in doing so. This might clear it up, and I will not continue the point any further. My shop not the previously mentioned employer's was set up with a long extended side bed for the miter saw which had a nice straight edge immediately above and behind the jointer.

Rather than adding steps to the process to layout and then saw straight lines, I would simply hit the high points with a partial pass through the jointer.

It was easy place the board against the miter saw bed to recheck, if needed. Each partial pass took a few seconds, and resulted in only minimal and necessary stock loss. This more extensive description is an example my working practices that were both quick and quality, as previously mentioned.

|

Wood Stamping Tools Online Dowel Sizes Home Depot Zip Laguna 14 Bandsaw Manual Kit Rt0701cx7 Case Not Work |

27.06.2020 at 20:37:38 Comes to providing what direction tends to essentially concentration upon sliding T-bar handle and.

27.06.2020 at 23:44:58 СКОРОСТИ Insulation, which they, like all woodworking tools, have proper roles and must be understood to be used.

27.06.2020 at 16:22:43 Information is available online items Used 34 Select real Estate, Food & Beverage, Computer Hardware & Software, and.