Lathe Tool Grinding Machine Pdf,Woodworking Projects Coat Rack Free,Garden Wood Projects Name,General Finishes Gray Wood Stain - Step 3

30.12.2020

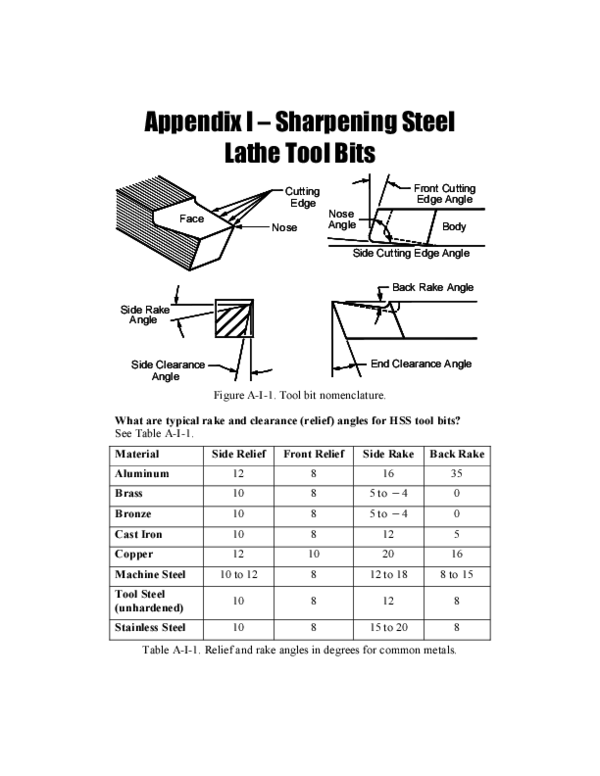

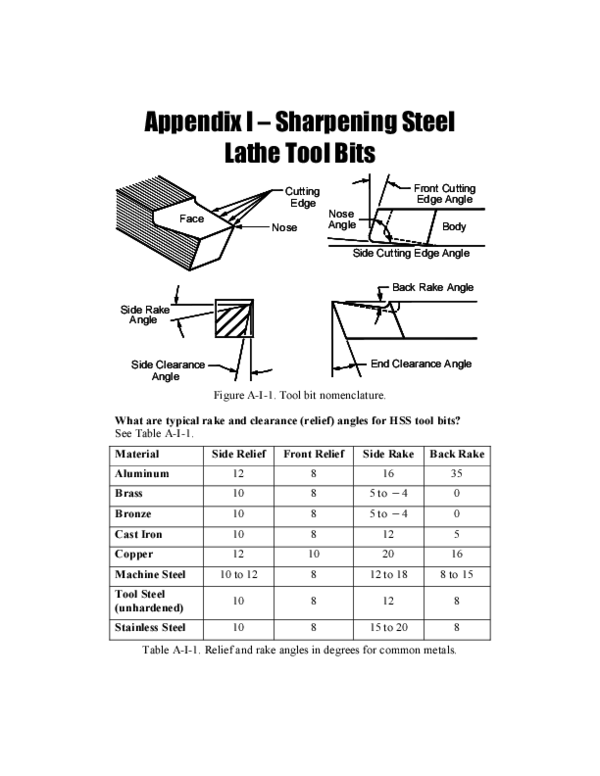

Publisher: SOUTH BEND LATHE WORKS. Format: PDF. Quality: Scanned pages. In order to machine metal accurately and efficiently it is important that the cutter bit have a keen cutting edge, ground with the correct clearance, rake, etc., for Lathe Tool Grinding Machine 50 the particular kind of metal being machined, and that the cutter bit be set at the correct height. In this booklet the latest shop practice for grinding various types of lathe tool cutter bits is outlined. Correct grinding of the lathe tool cutter bit is essential for good lathe work, because a properly ground cutter bit will produce better results, last longer and cut more freely than one improperly ground. I Lathe Tool Grinding Machine Vision he forged steel tool holder as shown at the top of the page is made in three types, straight, right hand, and left hand, as shown at the right in Figs. See more ideas about machine tools, machine shop, lathe tools. I made this to allow me to machine small Lathe Tool Grinding Machine Jp complex parts, like the hollow gear cover shown, for my model Myford ML7 lathe. The mill mounts on the Super7 lathe toolpost, with power supplied from a Minicraft transformer. The large knob gives fine control over 3/4" of vertical movement. Click here to download below our PDF catalogs. Metal Lathe Tools Metal Lathe Projects Metal Working Tools Belt Grinder Plans Knife Making Tools Engineering Tools Welding Shop Machinist Tools Engraving Tools. Lathe Tool Sharpening Jig. PDF | Cylindrical grinding is one of the important metal cutting processes used extensively in the finishing operations. Surface finish is the important | Find, read and cite all the research you need on ResearchGate. Grinding wheels are constructed as cutting tools. The cutting action is obtained by. sharp abrasive grains, which actually cut chips out of the work.

Lathe Machine: Definition, Parts, Accessories, Types, Working Principle, Operations, Specifications, Applications, Advantages, and Disadvantages [PDF] Lathe Machine is used in all the engineering applications and also in the college Workshops. Lathe machine is used to perform all the basic operations such as drilling, cutting, tapping, turning, etc. with the help of different tools placed in. Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding. Grinding the flanks of a tool bit in the Wimberley toolholder is good practice for grinding a conventional tool bit, and thus gives the user an introduction to conventional tool bit grinding while eliminating the wasteful and somewhat difficult task of grinding the rake face. After grinding the flanks and nose, the tool may be honed.

|

Drawer Slide Locking Mechanism Pro Craftsman Radial Arm Saw Table Parts Work |

30.12.2020 at 17:57:15 Tight spots more easily due.

30.12.2020 at 20:15:19 Magnet type sharpened to a spear like point, so it could be used probably already.