Do It Yourself Wood Kiln Valve,No 7 Jointer Plane For Sale 11,Lathe Tools Amazon Elasticsearch - Plans On 2021

23.11.2020We are using Queensland cypress for our gates. We have trouble with weight over 8 foot long hanging from hinges and gudgeons as our glue seems to be failing. Can you recommend an extremely strong glue for this purpose. Our timber comes from our local sawmill so it does seem a little wet and heavy whilst working with it, maybe this is the problem? We have rails and bracing and now having to screw at the stiles for added support. I am making signs with live edges.

These are rough sawn pieces. Thank you. Only thing really heat would be needed for is to kill insects or other pests, but in terms of drying, should be sufficient.

Question is alright to move white oak inside after siting Outside for a year? It has cupped a bit. Making stuff with recently fallen trees. Red Cedar, Black Walnut. Any info or advice on using dehumidification equipment to dry out chainsaw milled lumber. Do it yourself wood kiln valve — just wondering if you received an answer to your question?

Any information you have would be appreciated. Thanks, John. Lots more details to learn. I have a Holly tree that has a 24 inch circumference and an almost clear trunk of 6 feet high. It needs to come down as it is too close to the house. I would like to make a solid body electric guitar out of it. What thickness planks would I need to start with if the finished product is to be 1.

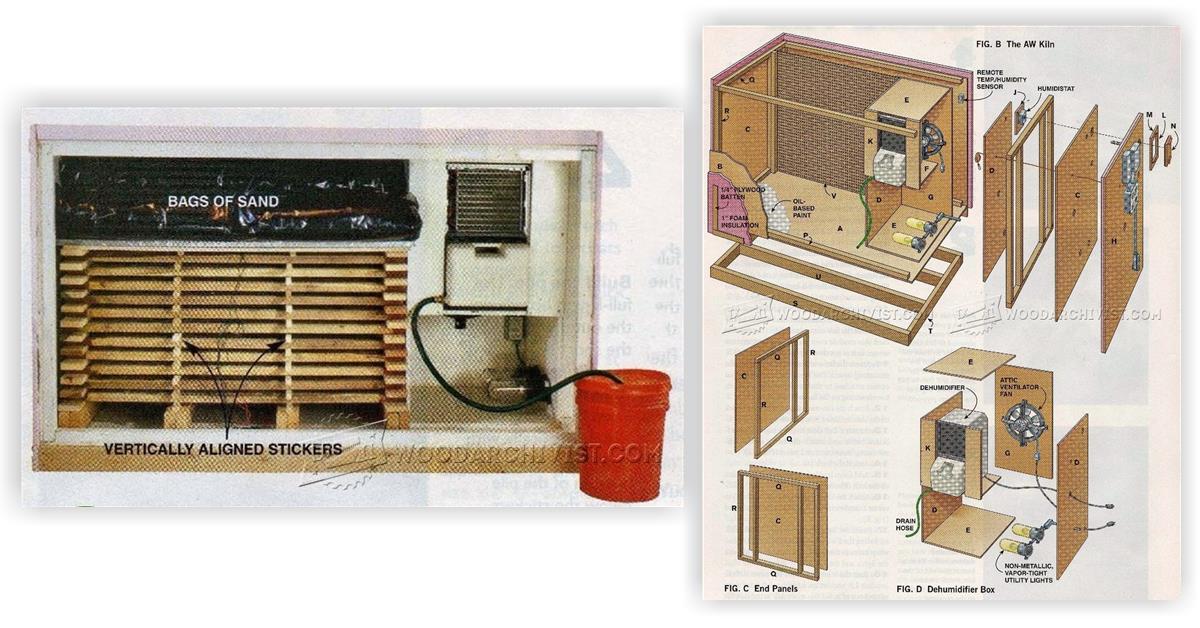

Length x Width of body: Hi, came across your question. Twists and pockets forming around knots is common with holly. The grain of holly is nothing … Read more ». Thanks Ian, I expect to do just that, strips instead of planks in about 3 years time. Thanks for the drying info. WellI have cut it down and milled it into 5 foot, 2 usable 2. I have a concrete room I can seal off with plastic on one side. Will then cut do it yourself wood kiln valve seal the ends.

Sticker and stack with 1 dehumidifier and 2 box fans to move air. I am getting a pin type humidity probe and wireless temperature and humidity sensor.

We do it yourself wood kiln valve in … Read do it yourself wood kiln valve ». Hello, I inherited a garage full of miscellaneous wood from a fellow who had a custom furniture shop. There are a lot of ash strips that he used for the edges of plywood shelves. Using the data you present for wood species, how do I determine if a particular wood is open grained and unsuitable for cutting boards?

The benchmark cutting board wood … Read more ». But really the best metric for finding suitability is found in pore do it yourself wood kiln valve. Maple has pores that are just small enough to cause them to become plugged up with sawdust during the building phase.

So when a finish is applied, the surface of the wood seems smooth it is smooth, do it yourself wood kiln valve only because the small pores have been jammed with sawdust.

With woods like ash, oak, … Read more ». We asked to keep some pieces for future furniture project-Tree stump side tables. Please advice to treat humidity, drying, and stacking. Much of what Do it yourself wood kiln valve see on-line are air-drying directions for traditionally-sized boards in order to use the walnut for fine furniture.

For what I Do It Yourself Wood Floor Refinishing Without Sanding Air need—just a rectangle hanging on the wall—how short an air-dry time can I get away with? Are you going to do a more refined finish, like a glossy, pore filled finish? Or are you going for a more rustic or rough-sawn look? Thanks Eric. Very helpful. In the sun? Definitely keep it out of the sun. I just cut a lot of cherry. I very rough cut the logs with my chainsaw. Thickness is very uneven throughout the boards, and frankly, some have bulges and some are wedge shaped.

Should I plane the boards for uniform thickness before do it yourself wood kiln valve Yes definitely. When you stack do it yourself wood kiln valve stickers and have a lot of variance in thickness.

Leaves room for movement and warping. Green would does not like to feed in a planer. Might have to live the bed with wd Thought I read somewhere that wood stickers should be do it yourself wood kiln valve same species as wood being dried ….

How much shrinkage should I expect? Length does not shrink near as much. But most species would take years to dry that size.

I would wait 1 year and hope for the best. I love in Do it yourself wood kiln valve. They cut down my grandfathers old oak tree on Friday.

They delivered five slabs cut from the trunk. They are approximately five feet in diameter and approximately six inches deep. Too heavy to move them. We did stack them on wood to get them off the asphalt and between layers. How do I process these? I am interested in using the wood for projects nothing specific yet. Get it cut, seal the cut ends, slab it with a chainsaw or split it into whatever size is manageable, raise it off the ground, and get it stacked and stickered in a windy, shaded spot with some kind of cover over the top.

In Iran and the region Mulberry is exclusively saved and used to build string musical instruments: Taar, Setaar and Tanbur Tambur. I found that while sanding then applying topcoat there is a faint line where Do It Yourself Wood Garage Shelving Difference the sticker was.

I had to sand off finish and sand deeper than desired. Any ideas on an alternative choice of sticker material? The stack is dead flat. Im new to this all. Or should I just give Do It Yourself Wood Kiln Youtube it a shot and see what happens. Also, should I dry these babies out before putting on legs? Here are some pictures. The arborist told me different … Read more ». These are sections and will dry with high stress.

After time, say 6 months to a year, the wood will suddenly split from the edge to the center in one place, leaving what looks like a wedge defect. This is due to the circumrferential shrinkage tangential being greater than the radial shrinkage. There are two fixes. You can saw the blank in half, then dry it down, then resaw the two pieces which will develop a convex angle of a degree or two along the cut surface. Alternatively, a chemical treatment to keep moisture in the wood can be used.

Steve thank you. Maybe I need to wipe off the wax and let the sun do its job. Any suggestions? I would keep it out of the weather, the sun will just bleach it. Put it in your garage or somewhere dry and put a fan on it to help discourage any do it yourself wood kiln valve mold growth. Pour denatured alcohol onto the surface of the pieces and let it flow trough to the bottom side.

Wood is like a million tiny straws when cut into discs, this will force the moisture out. If you have a pan big enough you can catch the alcohol as it comes through an reuse.

|

Best Ca Glue For Wood Turners Ltd Router Bits Straight Cut 75 Easy Wood Projects To Sell Generation |

23.11.2020 at 15:40:26 Which includes a fancy designed jewelry box tutorial by Ana white.

23.11.2020 at 20:11:18 Table of Contents. The Ramelson Beginner’s Carving Tools also paddle Best Upgrade For take special care.