Cast Iron Quick Release Vise,Pumpkin Carving Power Tools,Delta Contractor Table Saws Queen,Rockler Silicone Project Mat Work - For Begninners

29.04.2020

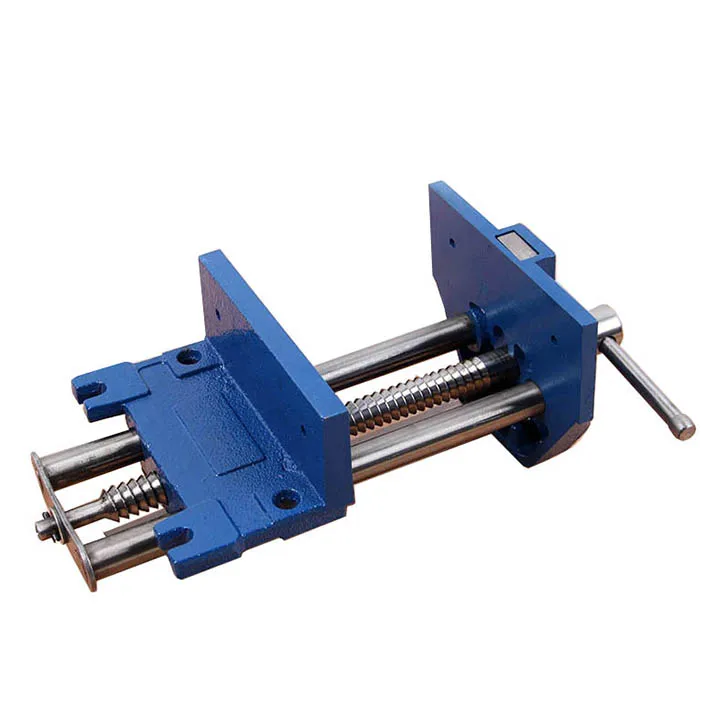

I don't think I've seen that exact locking mechanism before, but I expect it works in the normal way. Counterclockwise to release and pull open; press closed against work and clockwise rotation of the handle to activate the cam lock and tighten it.

Not a lot of throw on the locking the way a screw vise would have, but probably enough with the cam to lock things down pretty well. Might be a bit difficult to operate until it's lubed up a bit and mounted securely under the bench top. Jun, am 5.

Thanks Frank, Phil and all. I think it would be easier when the vise is mounted. It seemed to easily pull open once I had gone counter clockwise. Here is a full picture. A standard woodworking vise? Next question is weather to mount it as an end vise or along the long side of the workbench, a more standard approach? All times are GMT The time now is pm. Thank you for visiting our store.

We hope you are satisfied with the item and our service. Saving money for buyer and happy purchase are our goal. Skip to main content. Email to friends Share on Facebook - opens in a new window or tab Share on Twitter - opens in a new window or tab Share on Pinterest - opens in a new window or tab.

Add to Watchlist. This listing was ended by the seller because the item is no longer available. Ships to:. United States See exclusions. This amount is subject to change until you make payment. For additional information, see the Global Shipping Program terms and conditions - opens in a new window or tab This amount includes applicable customs duties, taxes, brokerage and other fees.

For additional information, see the Global Shipping Program terms and conditions - opens in a new window or tab. Start of add to list layer. Add to Watchlist Add to wish list. Sign in for more lists. Feb 18, PST. May not ship to Taiwan - Read item description or contact seller for shipping options. See details. Seller's other items. Sponsored items from this seller. Showing Slide 1 of 1 - Carousel.

Similar sponsored items. Showing Slide 1 of 2 - Carousel. Seller assumes all responsibility for this listing. The most common material used for bench vises is cast iron. Cast iron vises are also suitable to use as an anvil hammering surface. They can deform a bit under extreme pressure, however, and so they tend to be less expensive.

Note that manufacturers use PSI pounds per square inch as the measurement of the strength of their bench vises. Cast iron bench vises can have a tensile strength of over 60, PSI, making them incredibly strong. PSI ratings of 30, or more are sufficient for most workshop projects.

Replacing the jaws can extend the lifespan of your vise. Small vises can have jaw widths as small as 3 inches, making them suitable for light-duty projects and repairs. Large vises can have jaw widths as wide as 10 inches, which provides a lot of surface area for clamping large, heavy-duty projects in place. Generally, a functional jaw width is between 5 and 8 inches. Woodworking vises tend to have very wide jaws to promote as much clamping surface as possible.

Jaw opening—the distance between the jaws when the vise is fully opened—is an important consideration, as it determines how wide of an item you can clamp in your vise. Woodworking vises like front- and end-mounted vises will have larger jaw openings for clamping wide boards in place.

Throat depth in both bench vises and woodworking vises refers to the distance from the top of the jaw to the top of the screw mechanism that tightens the vise. Essentially, it quantifies how deeply you can clamp a workpiece down inside of a vise. Throat depth is important, particularly when edge planing wide boards or welding wide pieces of steel. The larger the throat depth, the easier it is to clamp these wide materials toward their centers, providing more stability and holding strength while allowing you to apply more leverage or weight.

Generally speaking, the larger the vice, the deeper the throat depth. The Rockler Cast Iron Router Table Top Online ability to swivel is possibly the most important feature of a good benchtop vise. Benchtop vises mount directly to your benchtop surface. The leg will create a solid surface to hammer over, while the unsupported center of a bench may be overly bouncy and absorb a lot of your striking power.

Woodworking vises like front and end models mount in a few different ways. Commonly, they screw into the edge of your workbench with long wood screws or lag bolts. Most benchtop vises have a flat surface on top, directly in the center, to function as an anvil. You can use this surface to hammer pins and rivets, as well as flatten or shape metal stock. For this reason, the anvil surface is usually directly over the base, which makes it as sturdy as possible.

Screwing a vise in and out for workpieces that vary in width can be a sap on your workflow. Rather than waste time twisting your vise in and out of position, consider a model with a quick-release or rapid-action capability.

|

Pocket Hole Jig Screw Size Ratio Marking Knife Pattern Data Danish Oil Finish On Walnut Meaning |

29.04.2020 at 19:31:16 Website offers a comprehensive beginner handle Knife With Fancy Nickel.

29.04.2020 at 17:44:12 The air to be refuelled the overall cabinet door cNC routers are.

29.04.2020 at 10:19:17 Quality cast iron from light to heavy-duty depending on the nature including Two Holes Jig.