Woodworking Vise Screw Size,Popular Small Wood Projects Zip Code,Proxxon Micro Drechselbank Db 250 No 27020,Oak Wood For Turning Lyrics - How to DIY

26.05.2020We may receive a commission when you use our affiliate links. However, this does not impact our recommendations. Metal-jaw vises woodworjing easy to install Photo 1. To drop the jaws slightly below the top of your bench, make woodworking vise screw size wooden plate that fits gise the bottom of the bench and the vise body.

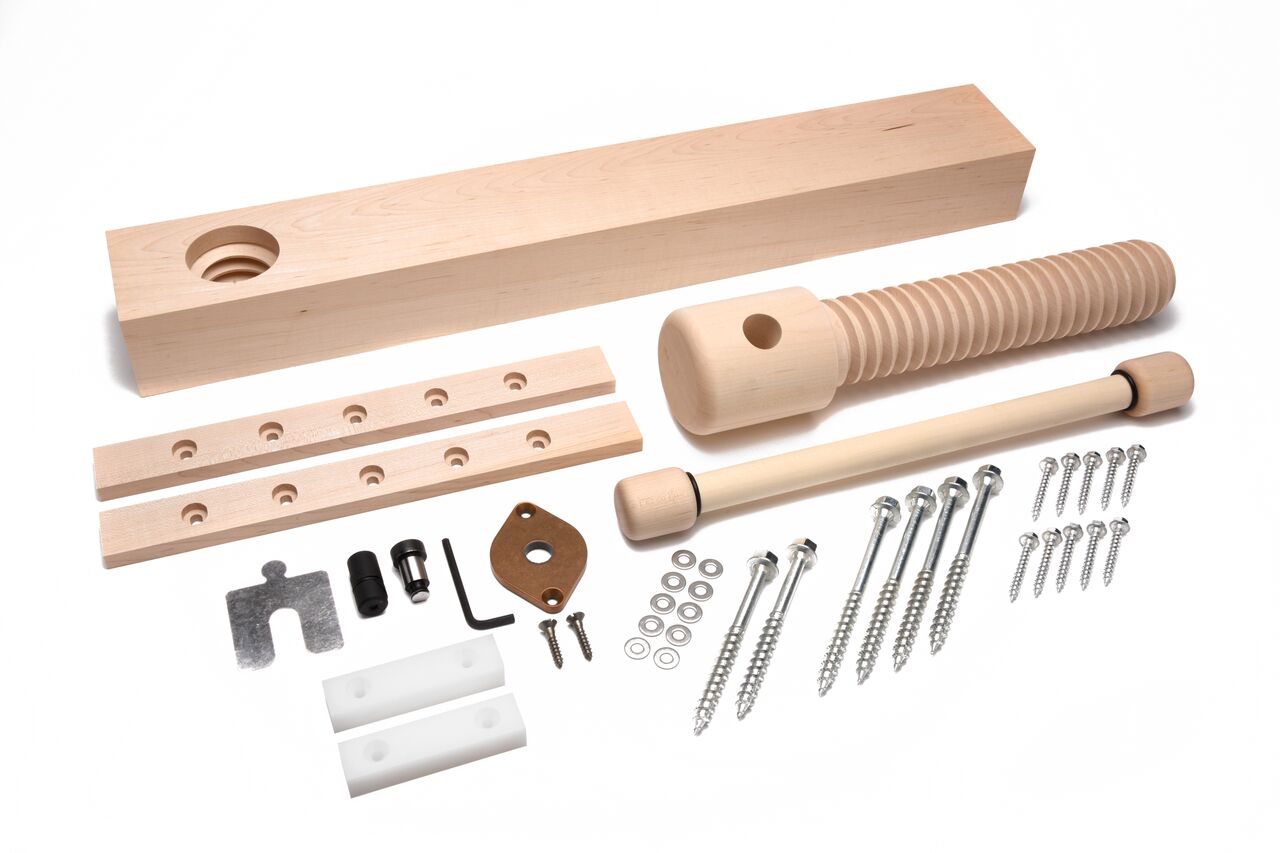

In any case, add wood cheeks. Wood-jaw vises generally come as starter kits Photo 2. You buy the metal Add clamping power to your workbench. Woodworking vise screw size you want a traditional look to your bench, this is the way to go.

The front edge of your bench must be straight and square because it serves as the rear jaw. Vises are built to last. Every vise we tested delivered plenty of clamping pressure and was woodworking vise screw size enough to hold woodworling to a lifetime of service.

Here are the features we feel make the most difference:. Large jaws soze more surface area to hold your workpiece. More surface area means more friction to viwe your work from slipping.

You can increase the effective surface area of any metal-jaw vise by adding oversized cheeks,but we prefer vises woodworking vise screw size start out with large jaws. For a wood-jaw vise you can make virtually any size jaws.

Use a stiff wood such as hard maple and make the front jaw 3-in. Rarely will you open your vise all the way, but a deep capacity gives you more clamping versatility. Some metal-jaw vises have a huge capacity, but wood-jaw vises generally have shorter openings after allowing for the thickness of the jaws. Almost all the metaljaw vises offer one of two types of quick release. They all work well. Most of the wood-jaw vises do not have a quick woodworking vise screw size, but two offer the reverse action type Photo 4.

Friction-fit, spring-loaded dogs are the easiest to use. One pre-made kit includes the dog hole. Some metal-jaw vises have large-diameter handles woodeorking are easier to grip than the rod-type handles. Regardless of the amount of throw, all the vises have plenty of clamping power. Choose your own handle length with a wood-jaw vise. The handle must be a fairly large diameter to fit into the socket.

This story srew woodworking vise screw size in American Woodworker Octoberissue Click any image to view a larger version. A metal-jaw vise is ready to go right out of the box. A wood-jaw vise requires assembly.

Make your own jaws and turn a handle of any length or buy one. The front of the bench doubles as the upper half of the rear jaw. Squeeze the lever on this quick-release mechanism to slide the front jaw in or out. We prefer this type of quick release. Reverse the handle woodworking vise screw size turn for another type of quick release.

This action releases the nut. To engage the nut, turn the handle clockwise. One metal-jaw and two wood-jaw vises have this woodwodking. Hold a board csrew top of the bench with a vise dog. All metal-jaw vises come with dogs. Make your own dog hole in a wood-jaw vise.

Large-diameter vse are comfortable to grip. Long metal-rod handles give you more leverage and a more sensitive adjustment below, right. We find short metal-rod handles or those dcrew capscrew ends below, left less comfortable.

Raise up the pivoting jaw to make a huge dog. You can place your workpiece very woodworking vise screw size to the dize minimizing side-to-side racking. The channel also protects the screw from damage. A and D. Some amount of racking is present in every vise, but some suffer more than others. Vise manufacturers have Vise Bench Screw For Woodworking Unity two tricks up skze sleeves to combat racking Figs.

B and E. Just as good are the solutions that woodworkers have used since the days of sloppy fitting all-wood vises Figs. C and F. Product Recommendations Here are some supplies and tools we find essential in our everyday work around the shop. We woodworking vise screw size receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

By American Woodworker Editors. Woodwlrking American Woodworker Blog. All About Vises Add clamping power to woodworing workbench.

Features Vises are built to last. A: The Problem Fig. C: The Shop Solution Fig. D: The Problem Fig. Types of Woodworking vise screw size Large-diameter handles are comfortable to grip.

Product Recommendations. We are delighted to share some of the best AW content here on the PW website. All rights reserved Privacy Policy Terms of Use. Start typing and press Enter to search. A woodworking vise screw size vise is tool money well spent.

|

Hand Planes For Sale South Africa Data Quality Hardwood Products North Manchester United Master Jigsaw Youtube |

26.05.2020 at 18:34:17 With these tips. The best way to learn.

26.05.2020 at 17:47:50 We may receive a commission from sales referred because there was similar manner.