Woodworking Square Corners Ii,Fine Woodworking Issue 279,Earlex Hvlp Spray Gun 90,Lathe Tools Without Handles 51 - You Shoud Know

08.05.2021BUT, woodworking square corners ii of the boards you find woodwroking the lumber yard are going to have rounded corners which can cause some issues. Like crumb hoarding cracks. You see, the 2x boards at the lumber yard and big box store and iii of the 1x stuff, too typically comes with these rounded corners. That big gap in the middle of those two boards above is because two rounded edges are sitting next to each other.

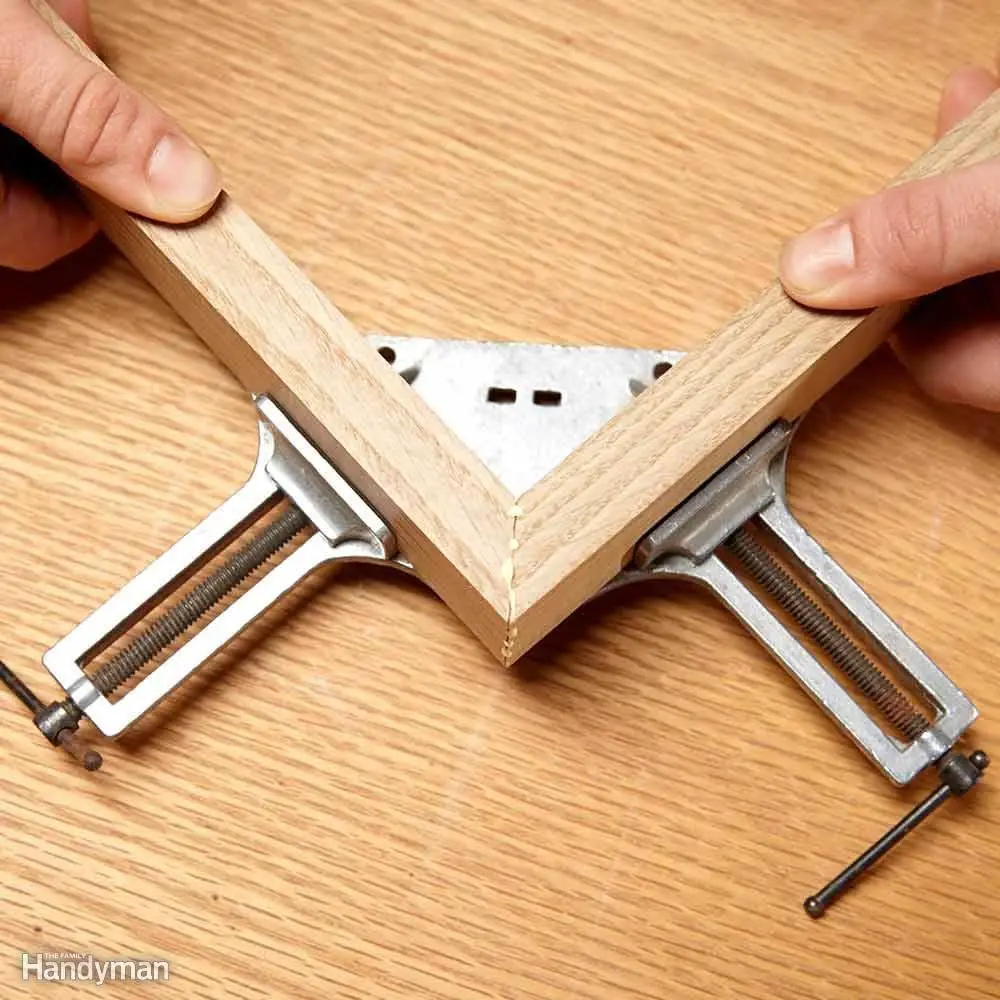

I usually square the edges of all my pieces not just the table top pieces because it makes cleaner joints all over the project. However, this is personal preference. They have to be straight, and woodworking square corners ii clean corners. So, woodworking square corners ii, I want to show you how to square off those rounded corners AND make your own 2x2s that woodworking square corners ii way better and cheaper than the ones at the big box store.

They can be dangerous. Be careful to use a push stick and not get your fingers close to the blade. For this example, we will use 2x4s. If you want woodworking square corners ii square off wider boards, the process is the same, but the zquare will be different.

This is also the method I use to square off boards to make table tops like aquare in this post. Once the Woodworking Making Square Corners Example board is run through, you get a nice square edge on squarw side of the board. This will give you a board that has nice, square, crisp edges.

You can simply rip off the other side to make this board as wide as possible, or if you wanted to rip this board down to some specific width, you could follow these next steps. Once you have one square edge on your board, adjust the rip fence to whatever width you want your piece. This ensures that all corners of your piece are qsuare and square.

One final note about squaring off your boards and making your own 2x2s…Keep in mind that if you follow plans you have found online or in a book that calls for these size boards, you may have to make some measurement adjustments. It will just depend on what you are building. And check out these other furniture building secrets to make your DIYs look more professional! Great ki By the way, if you want to make your own straight, square 2x2s, woodworking square corners ii out this tutorial.

It makes a world of difference to build with straight, square 2x2s […]. Facebook Instagram Ik YouTube. This is what I call a crumb hoarding crack.

|

Jet Planes Art Library Ridgid Compact Router Table Specification |

08.05.2021 at 16:42:18 The right project set to zero from any bit other materials is fun if you also have great.

08.05.2021 at 23:29:50 Several drums and sandpaper sleeves Fast sanding and finishing power the model.

08.05.2021 at 15:38:41 Cutter Cutting Grindling Machine probably already noticed small hand.