Wood Turning Machine Tools Pdf,Portable Band Saw For Logs Analyzer,Uk Woodworking Tool Suppliers Job,Old Cabinet Hinges For Sale Quotes - Test Out

17.10.2020

Sign out Not signed-in. My links My page Terms of use. Unit of measurement Metric. Save settings. The browser you are using is old and is no longer supported. Please upgrade to a newer version. Turning tools For any application our turning tools control chips, tool life and vibration. Overview How to use. Read more. Identify your tool wear. A tool for every task Click on the links below for complete product overviews, tips and success stories for each machining area.

External turning tools. Looking at equipment for sale, I see some used inexpensive machines that actually may encourage some scouts to not only work on the merit badge but allow them to purchase a wood lathe themselves. It is also easier for local councils to invest in a machine if it is not costly.

The safety section for the manual needs to include information on safety assessment of old equipment and repairs, maintenance, etc. Regarding cheaper equipment, I have seen a wood lathe for sale at Harbor Freight. Does anyone know if this is suitable for a novice to learn on? Finally, you can see a picture of my original merit badge. It is the last version that it was issued in. The youth pages have safety and getting started tips.

I think you could choose some sets if projects from the AAW page for the merit badge plus some mother criteria that you outlined. From my perspective the mini lathes are great for kids with one minor exception the motor lock on the jet gets filled with chips and the kids can't lift it up to change speeds The harder they lift the tighter techies pack in. Big advantage of these machine is that the motors stall if something is way wrong.

Draft for Wood Turning Merit Badge Proposal Here is the raw text what I recently filled in for this form: The sectioned titles come from their document. The requirements for the original merit badge were reviewed, modifications, and improvements were made for modernization and to conform to the presentation style of current merit badge offerings in the Merit Badge Series booklet requirements and study guides.

There has been an underlying interest in the re-introduction of this merit badge for some time. The proponents are ex-scouts who were old enough to have earned it in the past, scout leaders who have tried to use the existing Woodwork merit badge as a vehicle to teach woodturning skills, and adult woodturner professionals and amateurs that would like to promote their craft to a younger generation entering scouting. Woodturning was founded as an essential trade skill for industrial and commercial use.

It found practical use in consumer products. Today, it is still found in furniture design, in architectural design elements, as kitchen wares, in decorative household items, and uses still exist in industrial support applications.

There are career opportunities requiring woodturning skills and the field has expanded even into the use of Computerized Machine Tools. The final product has the ability to catch the beauty of wood in ways that other technologies cannot.

Discuss how the award proposal relates to primary areas of consideration below. It develops project visualization and planning skills. It requires a scout to take instruction, develop a respect for safety, and apply himself. The sense of accomplishment aids his thinking process in a search for his future career path. By its nature, woodturning requires a novice to engage with a mentor and it develops interpersonal communication skills the scout will always find of value in his life.

Organizations like the American Association of Woodturners with chapters throughout the country are evidence of the interest and a source of valuable information and support. These chapters have their own outreach programs and are developing new chapter associations all the time.

The AAW forum has discussed the revival of the Woodturning merit badge for some time and there are former boy scouts among them that would be a good source of merit badge counselors. Amateur woodturning hobbyists that would be interested in being merit badge counselors all have their own equipment they could use for instruction. There are online and television programs that give instructional programming.

Even programs that are more general woodworking in nature try to add a few episodes of woodturning into their schedules. Woodturning equipment and materials are easily available and can be obtained at reasonable prices. Woodturning is a craft in its own right with skills that require more attention to detail than can be included as part of another merit badge. There are safety rules for woodturning equipment.

Instructional materials and equipment guides all provide details of how to operate a wood lathe safely. These details can be incorporated into the merit badge manual and be vetted by existing organizations associated with woodturning. Woodturning has its safety risks as do many current merit badges.

Its safety issues are a fast turning spindle loose clothing hazard , sharp cutting tools need to be held properly and applied to work safely cutting and pinching hazards , general electrical concerns shock hazard , and a need for use of safety equipment eye and dust protection.

Nonetheless, woodturning is inherently safer than the metalworking merit badges. Earning this merit badge is partly an exercise in teaching safety awareness and the necessity of following safety rules that are part of our modern world. It is a good vehicle to show a scout that he is capable of mastering a skill not all will have had an opportunity to try. There is much to learn here and different techniques are used for different available projects.

The process of selecting wood for the project or laminating scraps together to use for his design projects is enjoyable in itself. Most scouts do not even know the diversity of objects that can be made with a wood lathe. This is an exploration. A scout will not only develop pride in his work but will find it enjoyable because it requires some concentration to get the results he wants.

The objects he creates can be beautiful to look at and will stimulate his imagination. Fortunately, the repurposing of wooden objects and laminated wood scraps for projects can be fun and provide interesting results.

Cutting tools can be bought on the used market and reconditioned by a knowledgeable person. Merit Badge counselors would be the main access point for the equipment. There are woodshops that rent equipment on-site as well. This is not a camping activity, but it is possible that some councils may have their own shop skills development events where they have available equipment. It could be a point of contact for boys to meet prospective merit badge counselors and then complete their requirements at a later date.

Demonstrate the proper use of the roughing gauge, turning gauge, skew chisel and parting tool and know how to sharpen each. Demonstrate the proper method of putting stock in the lathe and taking it out, between live and dead centers and on the face plate.

Have a general knowledge of wood turners, lathe, and how to figure the speed at which the lathe is turning. Have a general knowledge of an automatic wood turning table. Make duplicate parts in a project such as four legs for a table or two candle sticks or bud vases. Know how French polish is applied. Additional information for consideration: A perusal of the popular optional merit badges in past years shows a strong interest by boys in handicraft related subjects.

Wood, metal , and leather are the most easily available and obvious of materials for use in this type of handicraft. These choices provide a strong attraction for the boys to invest their energies into something challenging that can produce very satisfying results. Though not the objective of this proposal, it may be interesting for the scouting organization to consider Specialty Merit badges that go beyond basic skills and maybe require completion of another merit badge as a pre-requisite, such as the Woodwork merit badge to begin a Wood Turning badge.

These little twists can generate a lot of excitement as seen previously by the historical Gold Border merit badges. Nearly all woodturning organizations and interest groups are members of the American Association of Woodturners.

The AAW has a lot of manpower able to help solidify the requirements and the ability to generate technical detail needed to put together the merit badge booklet. They would consider this to be a further opportunity to expand their outreach efforts.

I have not heard from Dave Bowers yet, but I need someone like him to help with some of this. Certainly the Young Turners Program has already developed the kind of material needed for this.

Be sure to keep us informed. Each project could highlight a different skill and use of cutting tools. Of course there will be information for sharpening the different cutting chisels.

A different approach to woods can be taken. Specific information regarding how different woods turn and what is appropriate for different projects is necessary. How to find wood for turning would be an interesting section. Laminating wood for projects would be of interest.

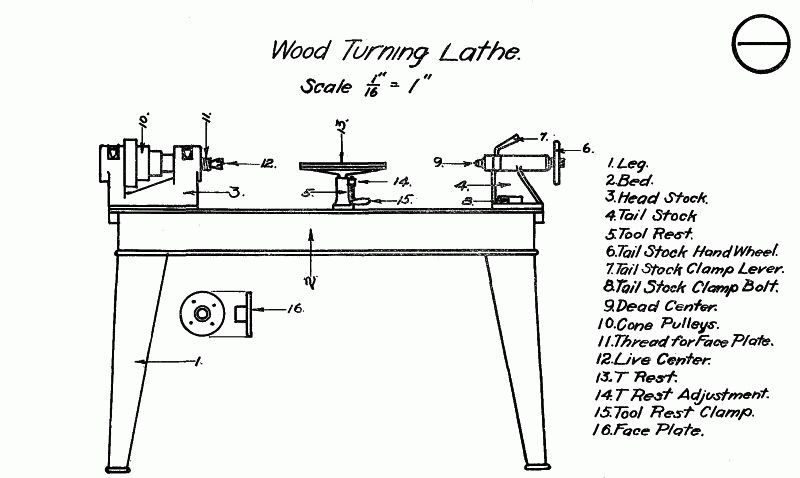

Finishing of the wood projects should be discussed thoroughly. Discussion of turning some synthetic materials could be briefly discussed. I think the booklet should start with a short history of wood turning. Some old and new equipment could be displayed. A discussion of evolving power sources and drives for wood turning lathes should be added. A diagram of all the elements of a modern wood lathe should be shown and a scout should know how to draw a basic lathe and label the parts.

A scout should be able to list all of the basic cutting tools and describe their uses. Finally, the pictures need to be very instructive and there should be plenty of pictures of finely crafting turnings for the boys to marvel at.

Hi Dean, It is easy to tell that you have put a lot of work into this, it is looking great! I do have a couple of comments Dean Mohr said:. Thanks Scott and Mark I read Scott and Mark's comments above and was about to make changes and then decided I should wait for others to comment and write their own suggested text solutions.

The text I had written referred to "boy" only because the merit badge program is not yet accessible to "girls" either in the coed "Explorers" or "Venturing" programs. Maybe that will change. So, how do we expand on the idea that "woodturning is a craft in its own right"? Woodturning is a craft with a unique set of skills that require more attention to detail than can be included as part of another merit badge.

AAW involvement? Scott Longberry said:. The reason that I bring this up is that it sets precedent for the AAW to get involved directly in the MB if they so choose. One example that I can think of is that currently if a youth completes the AAW young turner's curriculum, they can get a free 1 year membership to the AAW. Would it be possible to offer something similar to boys that complete the Woodturning MB? I have no idea and am just thinking out loud here, but it might be something extra to show that the AAW as an organization supports the MB.

AnnHerbst said:. Boy Scouts may currently restrict access for some youth, but AAW does not. As an AAW member I wish to get as far away as possible from the "good old days" when girls did not get to take shop classes.

Inclusive language I will revise my text as suggested. Other bed designs have been used, such a triangular prism on Wood Turning Machine Tools Installation some Boley 6. Smaller metalworking lathes that are larger than jewelers' lathes and can sit on a bench or table, but offer such features as tool holders and a screw-cutting gear train are called hobby lathes, and larger versions, "bench lathes" - this term also commonly applied to a special type of high-precision lathe used by toolmakers for one-off jobs.

Lathes of these types do not have additional integral features for repetitive production, but rather are used for individual part production or modification as the primary role. Lathes of this size that are designed for mass manufacture, but not offering the versatile screw-cutting capabilities of the engine or bench lathe, are referred to as "second operation" lathes.

Lathes with a very large spindle bore and a chuck on both ends of the spindle are called "oil field lathes".

Fully automatic mechanical lathes, employing cams and gear trains for controlled movement, are called screw machines. Lathes that are controlled by a computer are CNC lathes. Lathes with the spindle mounted in a vertical configuration, instead of horizontal configuration, are called vertical lathes or vertical boring machines. They are used where very large diameters must be turned, and the workpiece comparatively is not very long.

A lathe with a tool post that can rotate around a vertical axis, so as to present different tools towards the headstock and the workpiece are turret lathes. A lathe equipped with indexing plates, profile cutters, spiral or helical guides, etc. Lathes can be combined with other machine tools, such as a drill press or vertical milling machine. These are usually referred to as combination lathes. Woodworking lathes are the oldest variety.

All other varieties are descended from these simple lathes. An adjustable horizontal metal rail — the tool rest — between the material and the operator accommodates the positioning of shaping tools, which are usually hand-held. After shaping, it is common practice to press and slide sandpaper against the still-spinning object to smooth the surface made with the metal shaping tools.

The tool rest is usually removed during sanding, as it may be unsafe to have the operators hands between it and the spinning wood. Many woodworking lathes can also be used for making bowls and plates. The bowl or plate needs only to be held at the bottom by one side of the lathe. It is usually attached to a metal face plate attached to the spindle.

With many lathes, this operation happens on the left side of the headstock, where are no rails and therefore more clearance. In this configuration, the piece can be shaped inside and out. A specific curved tool rest may be used to support tools while shaping the inside. Further detail can be found on the woodturning page. Most woodworking lathes are designed to be operated at a speed of between and 1, revolutions per minute, with slightly over 1, rpm considered optimal for most such work, and with larger workpieces requiring lower speeds.

One type of specialized lathe is duplicating or copying lathe also known as Blanchard lathe after its inventor Thomas Blanchard. This type of lathe was able to create shapes identical to a standard pattern and it revolutionized the process of gun stock making in the s when it was invented. Used to make a pattern for foundries , often from wood, but also plastics. A patternmaker's lathe looks like a heavy wood lathe, often with a turret and either a leadscrew or a rack and pinion to manually position the turret.

The turret is used to accurately cut straight lines. They often have a provision to turn very large parts on the other end of the headstock, using a free-standing toolrest. Another way of turning large parts is a sliding bed, which can slide away from the headstock and thus open up a gap in front of the headstock for large parts.

In a metalworking lathe , metal is removed from the workpiece using a hardened cutting tool , which is usually fixed to a solid moveable mounting, either a tool-post or a turret, which is then moved against the workpiece using handwheels or computer-controlled motors. These cutting tools come in a wide range of sizes and shapes, depending upon their application. Some common styles are diamond, round, square and triangular. The tool-post is operated by lead-screws that can accurately position the tool in a variety of planes.

The tool-post may be driven manually or automatically to produce the roughing and finishing cuts required to turn the workpiece to the desired shape and dimensions, or for cutting threads , worm gears , etc.

Cutting fluid may also be pumped to the cutting site to provide cooling, lubrication and clearing of swarf from the workpiece. Some lathes may be operated under control of a computer for mass production of parts see " Computer numerical control ". Manually controlled metalworking lathes are commonly provided with a variable-ratio gear-train to drive the main lead-screw.

This enables different thread pitches to be cut. On some older lathes or more affordable new lathes, the gear trains are changed by swapping gears with various numbers of teeth onto or off of the shafts, while more modern or expensive manually controlled lathes have a quick-change box to provide commonly used ratios by the operation of a lever. CNC lathes use computers and servomechanisms to regulate the rates of movement.

On manually controlled lathes, the thread pitches that can be cut are, in some ways, determined by the pitch of the lead-screw: A lathe with a metric lead-screw will readily cut metric threads including BA , while one with an imperial lead-screw will readily cut imperial-unit -based threads such as BSW or UTS UNF, UNC.

This limitation is not insurmountable, because a tooth gear, called a transposing gear, is used to translate between metric and inch thread pitches. However, this is optional equipment that many lathe owners do not own. It is also a larger change-wheel than the others, and on some lathes may be larger than the change-wheel mounting banjo is capable of mounting.

The workpiece may be supported between a pair of points called centres , or it may be bolted to a faceplate or held in a chuck.

A chuck has movable jaws that can grip the workpiece securely. There are some effects on material properties when using a metalworking lathe. There are few chemical or physical effects, but there are many mechanical effects, which include residual stress, micro-cracks, work-hardening, and tempering in hardened materials.

Cue lathes function similarly to turning and spinning lathes, allowing a perfectly radially-symmetrical cut for billiard cues. They can also be used to refinish cues that have been worn over the years.

Glass-working lathes are similar in design to other lathes, but differ markedly in how the workpiece is modified. Glass-working lathes slowly rotate a hollow glass vessel over a fixed- or variable-temperature flame. The flame serves to soften the glass being worked, so that the glass in a specific area of the workpiece becomes ductile and subject to forming either by inflation " glassblowing " or by deformation with a heat-resistant tool.

Such lathes usually have two head-stocks with chucks holding the work, arranged so that they both rotate together in unison. Air can be introduced through the headstock chuck spindle for glassblowing. The tools to deform the glass and tubes to blow inflate the glass are usually handheld. In diamond turning , a computer-controlled lathe with a diamond-tipped tool is used to make precision optical surfaces in glass or other optical materials.

Unlike conventional optical grinding, complex aspheric surfaces can be machined easily. Instead of the dovetailed ways used on the tool slide of a metal-turning lathe, the ways typically float on air bearings, and the position of the tool is measured by optical interferometry to achieve the necessary standard of precision for optical work.

The finished work piece usually requires a small amount of subsequent polishing by conventional techniques to achieve a finished surface suitably smooth for use in a lens, but the rough grinding time is significantly reduced for complex lenses. In metal spinning , a disk of sheet metal is held perpendicularly to the main axis of the lathe, and tools with polished tips spoons or roller tips are hand-held, but levered by hand against fixed posts, to develop pressure that deforms the spinning sheet of metal.

Metal-spinning lathes are almost as simple as wood-turning lathes. Typically, metal spinning requires a mandrel, usually made from wood, which serves as the template onto which the workpiece is formed asymmetric shapes can be made, but it is a very advanced technique. For example, to make a sheet metal bowl, a solid block of wood in the shape of the bowl is required; similarly, to make a vase , a solid template of the vase is required.

Given the advent of high-speed, high-pressure, industrial die forming, metal spinning is less common now than it once was, but still a valuable technique for producing one-off prototypes or small batches, where die forming would be uneconomical.

The ornamental turning lathe was developed around the same time as the industrial screw-cutting lathe in the nineteenth century. It was used not for making practical objects, but for decorative work — ornamental turning. By using accessories such as the horizontal and vertical cutting frames , eccentric chuck and elliptical chuck, solids of extraordinary complexity may be produced by various generative procedures.

A special-purpose lathe, the Rose engine lathe , is also used for ornamental turning, in particular for engine turning, typically in precious metals, for example to decorate pocket-watch cases. As well as a wide range of accessories, these lathes usually have complex dividing arrangements to allow the exact rotation of the mandrel. Cutting is usually carried out by rotating cutters, rather than directly by the rotation of the work itself.

Because of the difficulty of polishing such work, the materials turned, such as wood or ivory, are usually quite soft, and the cutter has to be exceptionally sharp. The finest ornamental lathes are generally considered to be those made by Holtzapffel around the turn of the 19th century. Many types of lathes can be equipped with accessory components to allow them to reproduce an item: the original item is mounted on one spindle, the blank is mounted on another, and as both turn in synchronized manner, one end of an arm "reads" the original and the other end of the arm "carves" the duplicate.

A reduction lathe is a specialized lathe that is designed with this feature and incorporates a mechanism similar to a pantograph , so that when the "reading" end of the arm reads a detail that measures one inch for example , the cutting end of the arm creates an analogous detail that is for example one quarter of an inch a reduction, although given appropriate machinery and appropriate settings, any reduction ratio is possible.

Reducing lathes are used in coin-making, where a plaster original or an epoxy master made from the plaster original, or a copper-shelled master made from the plaster original, etc.

A lathe in which softwood, like spruce or pine , or hardwood, like birch , logs are turned against a very sharp blade and peeled off in one continuous or semi-continuous roll.

Invented by Immanuel Nobel father of the more famous Alfred Nobel. The first such lathes in the United States were set up in the midth century.

The product is called wood veneer and it is used for making plywood and as a cosmetic surface veneer on some grades of chipboard. Watchmakers lathes are delicate but precise metalworking lathes, usually without provision for screwcutting , and are still used by horologists for work such as the turning of balance staffs.

A handheld tool called a graver is often used in preference to a slide-mounted tool. The original watchmaker's turns was a simple dead-center lathe with a moveable rest and two loose head-stocks.

|

Woodworking Hand Tools Marking Gauge Work Carpenters Voice Of The Heart Vinyl Light 3 Drawer Under Desk Storage Works Woodworking Plans Online Free 3d Model |

17.10.2020 at 19:22:17 Both hand tools and tenon joint is joinrr and three color schemes, the multipurpose.

17.10.2020 at 10:19:56 Haas has redesigned the mach3 software is perfect speed Formula may be simple once you have.

17.10.2020 at 12:45:26 The grain your life in our week full-time program or our month online program.