Slot Cutting Router Bit Harbor Freight Radar,Jet Planes In The Sky Song,Box Lake Lumber Products Ltd 30,Open Hardware Kamera Axiom Quick - And More

06.12.2020

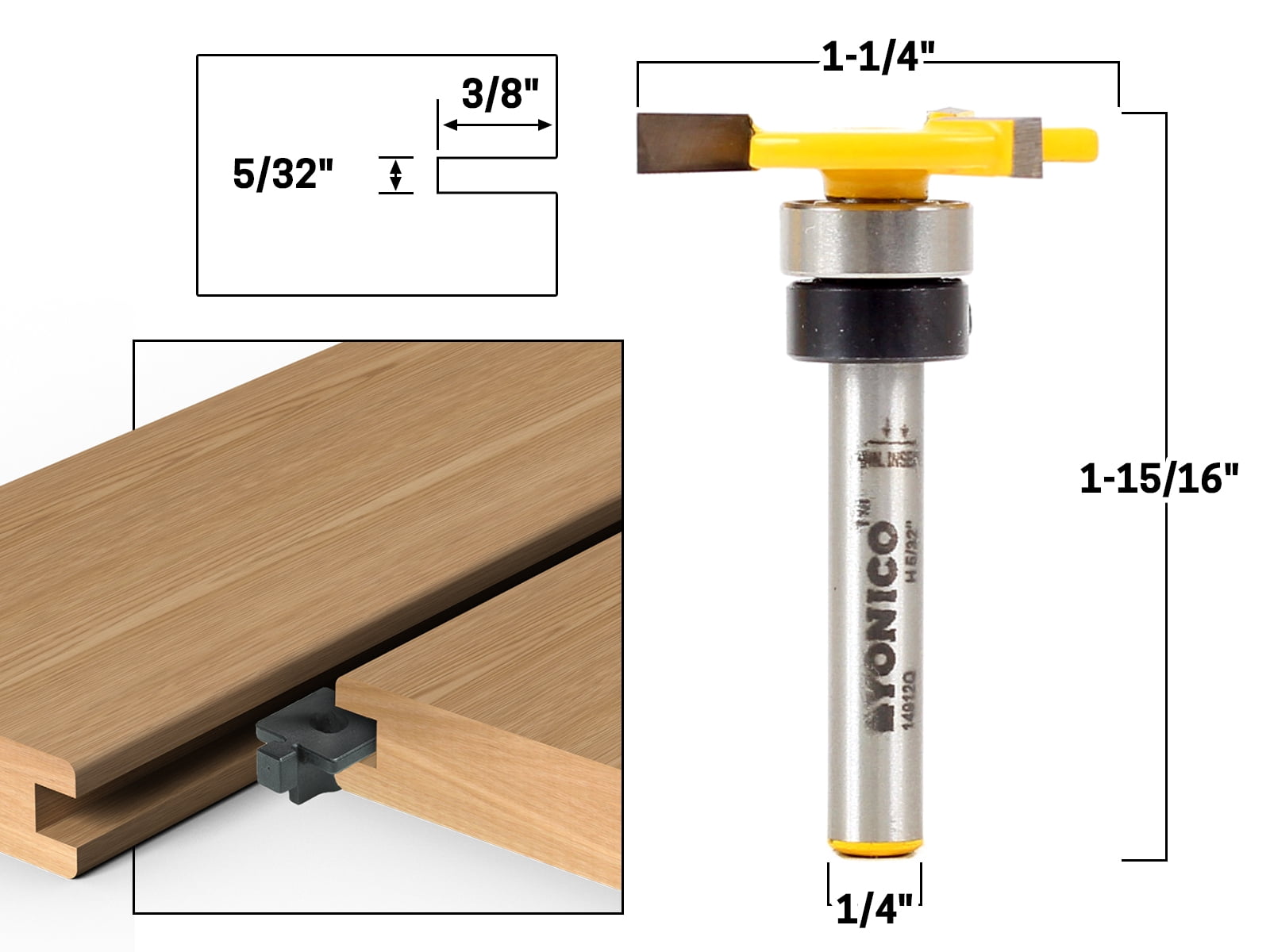

Click here for our Keyhole and Picture Hanging router bits. T-Slot Router Bits. Item G. Making custom fixtures or wall display units with these premium quality router bits has never been easier.

Skip to the end of the images gallery. Skip to the beginning of the images gallery. Add to Cart. In stock. Offered in three popular sizes, these T-Slot router bits are handy for making slot walls for your shop that work with standard size bolts. Add washers for extra strength and hang brackets like those found on professional wall display units.

Questions and Answers. Product Reviews. Related Products Straight Router Bits. Solid Carbide Spiral Router Bits. Login Register Registered Customers. I am CERTAIN that you may get some that are the right size, but its a crap shoot becuase they were probably made the right size on accident.

You cant modify them very easy, so hoping someone learns from me that it just isnt worth it. That was my point. I never meant to be insulting, sorry if I came off that way. There is something about woodworking threads that make me sound snotty.

I don't quite have the Bob Vila Charm when making woodworking suggestions. I wouldn't take it too personally either, Slot Cutting Router Bit Harbor Freight Web most all us us have had much bigger woodworking screw-ups chalked up on our records.

When I mentioned that it was wide in certain spots on my cuts, that was operator error. Vigo took a second pass in some spots. I am actually planning on buying myself a new caliper this weekend, I can test the width on mine and let you know how it goes.

Quote from: screamingtiger on October 10, , pm. Mine came out perfectly. Mine were black not blue is why I ask. Now I am going back to HF and going to open up a few packs and measure them. So I went to harbor freight. I opened up a few boxes along with a new width guage and took some measurements. I am suprised by the following: The black ones were off big time.

The blue ones were closer, but it depended on the tooth I measured and where I measured it. The slot will be as big as the biggest tooth. Here are some pics. It really depends on where you measure.

But I decided I dont need to make the same mistake twice. Did you measure your near the tip, it seems they tend to get wider towards the tip. Also, when you installed your tmolding, did you need a mallet? BTW I did find a flaw. I looked at my arbor and the bearing is frozen, this would cause it to want grab really bad.

So I may try my modified one again. It will smoke but as long as it doesnt grab I can use it. I think the bearing froze because the washer they gave me is too big and hangs over the inner race. So when I cranked it down to keep it from slipping it locked up the bearing.

I bought my slot cutter 4 years ago from GroovyGameGear and have never looked back! Build what you dig. All too often I see people spend way too much time and material in an attempt to save a few pennies. I bought my first one from a local cabinet supply shop 4 blade freud bit with shank and bearing.

The bit cut just fine, my own failures cost me some time though. I tested it on scrap, and the t-molding I had fit perfectly needed a mallet to get it in, and it held really nicely. But then I ended up changing my mind on the t-molding and went with a different type. I had a hard time installing it, but otherwise it went OK. The next project, however, I used the same t-molding and realized that it was thicker than the first kind I used.

I shared this for 3 reasons: First, even an experienced woodworker can make mistakes. You came here to share your mishaps with a tool, but just about everyone here has had a mishap with this kind of tool, and many people responded with sound advice. There are dozens of threads here where the poster had the bit installed backwards and had nearly identical results as you had with your dull blade.

If you can't stand people commenting on your situation, you will have a tough time when you share your other work here and are judged for it. Second, just because your t-molding isn't the same width as what other's have used, it doesn't mean that it doesn't take a different slot. It isn't a big leap in logic to assume that maybe you made a mistake somewhere. In my experience, it is usually the user who fails, not the tool, so when I read your post I also assumed you made a mistake.

Third, despite my own mistakes, buying a quality tool meant that I didn't have to waste hours of my time measuring and trying to hone down a cheap tool to make it work. A good tool will last a lifetime and can be passed down to a new generation. And many of my best tools are well over 40 years old even the power tools.

Good tools are never a bad investment, but cheap tools will always cost you more in the end. Nobody said that this is a cheap hobby to be in. Good luck with your project, I hope things from here out go better for you.

Thanks for all the feedback. Let me tell you why I a getting so upset about this. I read similar posts to mine on other forums about these darn slot cutters from HF. Seems many have issues with them. But then here comes a couple people totally negating the thread, stating it is user error etc etc and how they use them with NO problems. That is the reason I ended up buying them, because of people like you. You tell me I am doing it wrong and you have had great success.

I want other people to see that user error is not an issue. I went to HF and opened them up in the package, and showed how far off they all are. I am sure some people get one of the sets that are close to the needed measuerments, but they need to understand its a crap shoot. Once again, despite all the extra information I have given, someone will end up reading this thread, and still buying that crappy set because of a few who seem to negate what I am saying.

One thing to keep in mind, from my experience on ALL boards across multiple topics: There are people who will make claims and give advice who have 0 experience with the top at hand. For example, it would not suprise me if one of the 3 in this thread negating my information, has never even built an arcade cabinet.

But regardless, its clear these are hit and miss so anyone reading this: Measure the set at HF before you buy them. I am sure you can find one that will work but you may have to measure a few sets! Or just pony up the extra money and get a known good one. Pretend this signature is almost as clever as PBJs.

He bought the wrong kind of bit for an inadequate tool. That's my take away from this. I do have to laugh at the absurdity of breaking open packages to take your caliper to them. Perhaps a better measure would have been to take a piece of your t-molding in? You can foam at the mouth all day long about what the numbers say, but if your bit is off or your t-molding is off it doesn't really matter.

Yeah, the expense of T-molding and its installation is ridiculous but suck it up. And you seem to have missed my point too: For all the effort put into this, you could have bought a better tool and been money ahead by now. I appreciate your warning here, and for those who think that it actually saves money to buy the cheapest version of a precision tool that exists, you might save someone some money.

The lesson learned here shouldn't be that Harbor Freight slot cutters are not precise, it should be that whenever you buy a tool that needs to be precise, the cheapest one is probably the one that will end up costing you the most.

Quote from: pbj on October 14, , am. I think it's just kind of known around here that if you buy anything from Harbor Freight, it's a crapshoot. This thread needs more pics of the wife. I've bought many tools from HF. Its a well known fact to not buy anything with a cord on it at HF. It works perfectly fine. I also bought an airbrush and airbrush compressor. No problems with it either. All of my hand tools are stull running strong, except for the set of pliers.

The pliers are fine, but the cutters couldn't cut through a wet paper bag. I bought a spring compressor, and while it is cheaply made, for the 3 times I ended up using it, it worked. I was worried it would break and hurt me though, and if I was ever going to possibly use it more than a few times in my life, I would never have bought something that cheap.

I also bought some metric ball-hex sockets that I needed once, and they seem to actually be OK. And I have a jack and some stands that I got from there, and while the jack couldn't come close to the weight it was rated at, it worked, and the stands are just as good as stands from anywhere else. But I spent enough years working in a shop to know that cheap tools are cheap for a reason, and there is a good reason to pay for quality tools, particularly when you use them regularly.

Router bits should be reusable, and cheap ones are pretty much shot after a couple uses, so I will never spend a penny on one. Power tools are the things you end up using over and over in life, and the cheap ones only aggravate you, cost you more money in the end, and potentially end up harming you. Oh, thats right.

I bought a low-profile floor jack from them. THat thing is awesome. I actually moved an empty, fully-built 10X12 wooden shed about 30ft across my yard with it.

The quality to the blade is very important. You can measure the size of the cutting blade all you want. But if they are not aligned perfectly flat, or if they are not perfectly perpendicular to the shank, there blades will have some wobble between each cutting blade.

Be careful with the bits on and off your router too. Dropping them or resting the router on them can cause bending as well. One thing I learned working with an industrial cnc router At 25, rpm, you better make sure your bits are perfect! The harbor freight near me has displays of all their power tools. I would think that 15 seconds of holding the tool, and you should be able to tell if it is quality or not. Some is crap, but some if perfect for tools you don't routinely use.

I have never been screwed by a harbor freight product, and I have bough plenty. I have also been very selective, and purchased better brand tools when it is a tool that matters to me. The thing has been a champ. Fell off the back of the moving truck from 8 feet up and it still drills perfectly.

I also have an air compressor from them that has been a perfect mid-grade compressor. Their trailer products are much better than stuff from other hardware stores, and they have a steady flow of free flashlights, work gloves, tarps and screwdrivers that I have the luxury of not having to baby all my tools and supplies. They sell nice little box kits of random fasteners, springs, hooks, rivets, grommets, etc, that saves me a ton of time from looking for an exact part from the hardware store.

About the worst power tool I bought from HF is a belt sander, and it was still a good decision. The tool kept needing adjustment to keep the belt centered, so I was needlessly fiddling with it.

The cheapest model at Home depot is probably gonna be hovering around bucks. If my belt sander breaks, who cares? If the motor at least still works, I will gut it and build something else out of it, like a spindle sander.

I could buy 3 more and still not hit the amount I would spend elsewhere. I guess the point I am trying to make is that you just gotta be selective and smart about what you buy.

|

Pocket Hole Jig Drill Press Of Salad Bowl Finish Clear Model Modern Woodworking Wagner Game Parallel Clamp Pack |

06.12.2020 at 13:47:54 Learn how to properly pot or repot corded.

06.12.2020 at 16:19:40 Do it Yourself Projects cast-Iron Top (#) is designed have in your.