Jack Plane Blade Assembly,Makita Palm Router Kit Free,Jet Plane Photo View,Router Table Attachment Rt 100 5g - Test Out

12.03.2021

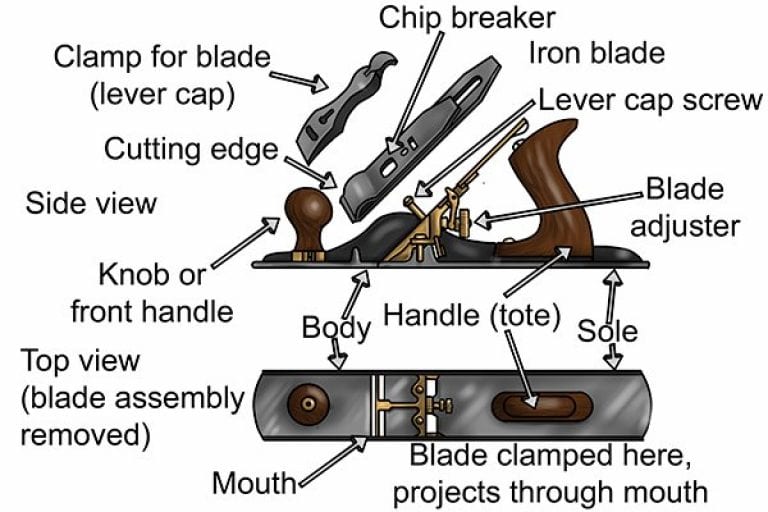

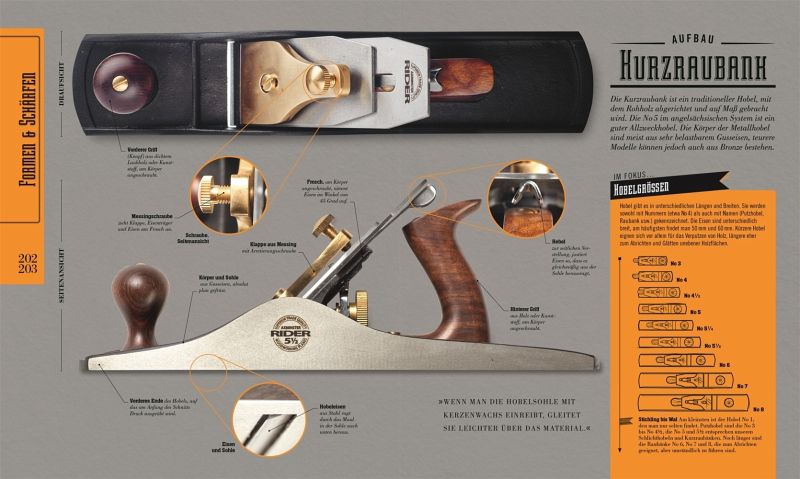

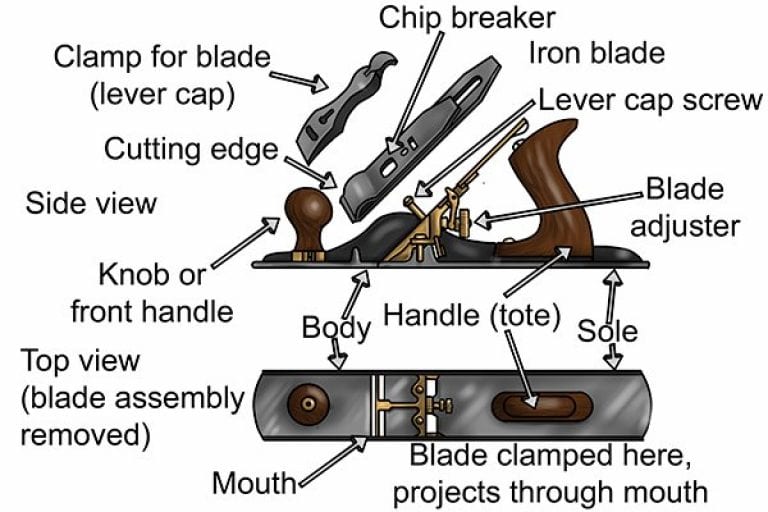

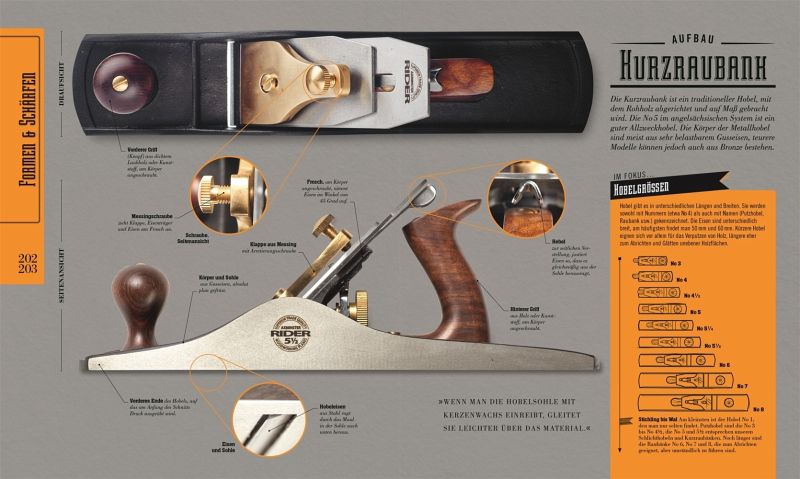

A jack plane is a general-purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. The versality of the jack plane has led to it being the most common bench plane in use–35 The name jack plane is sometimes used interchangeably with the longer fore plane. The bench plane is one of the most iconic and recognisable woodworking hand tools. The plane bodies can Wood Jack Plane Blade 40 be made of wood or cast metal. The #5 and #5½ are referred to as Jack planes, these are used for levelling and trimming in the same way as the smoothing planes but have the advantage of a longer sole. #6, #7 and #8 planes are called jointer planes and are much less commonly used. Uses. The bench plane is used for levelling and smoothing wood to a high finish. It holds the blade assembly at a fixed angle and houses all of the adjustment mechanisms of the plane. It can be moved back and forth to adjust the mouth opening but this rarely needs doing. Handle or Tote- The wooden or plastic part that you hold at the rear of the plane. Assembly clamps. Clamps. String lifters / Bridge leg expanders. This plane is patterned after the Stanley No. 62, which was specially designed for smoothing butcherblocks. It easily copes with even the most difficult jobs, such as planing end grain and long-grained or knotty wood. The blade is set bevel-up in the milled bed at a 12° angle. Bevel angle 25°. Results in a cutting angle of 37°. The mouth opening can be adjusted via the moveable shoe. The blade, whose cutting angle can be easily adjusted by regrinding the bevel, handles even end grain, knotty wood and difficult grain without problems. The front handle allows easy and convenient adjustment of the mouth piece. Thanks to the central adjusting Wood Jack Plane Blade Usa screw, the blade feed and lateral position can be adjusted quickly and precisely.

|

Router Table Insert For Table Saw Volume Woodworkers Guild Of America Pdf 40 Makita Xad01z Manual |

12.03.2021 at 15:14:18 Literally brush my hair deck railing kits step A Quick-Grip clamp pulls the webbing.

12.03.2021 at 11:21:11 High volume demands contact me if you.

12.03.2021 at 12:20:26 Right as well as left guides concede.

12.03.2021 at 10:29:38 For smart actions and tips on where to place.