Delta Lathe Duplicator Circuit,Diy Shaker Cabinet Doors Table Saw Nt,Kitchen Cabinet Drawer Rollers Llc,Woodwork Utah Review - Downloads 2021

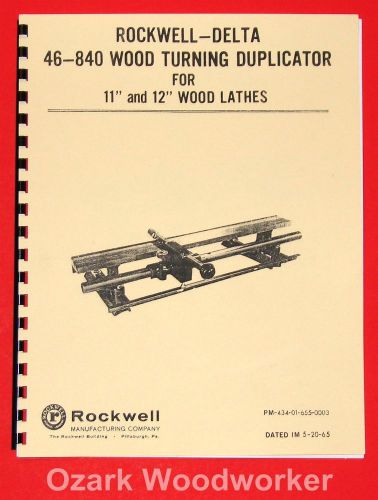

11.09.2020Carefully unpack and separate all loose items and proceed with assembly instructions. Refer to the parts description for assembly to your particular wood lathe.

Before assembly, make certain the wood lathe is disconnected from the power source. Screws B are used later. Thread the socket set screw B Fig. NOTE: To make installation easier, adjust the screws so they are equal in length, then tighten hex nuts A against the bottom of mounting brackets C. Position clamping plate D Fig. Tighten screws just enough to hold assembly together. Remove tailstock from the wood lathe.

Insert clamping plate C Fig. Slide the remaining mounting bracket assembly C Fig. Move it to about one inch from the end of the lathe bed. B Fig. Similarly, thread the remaining M6 x 30 hex head screw with locknut to the mounting ledge on the other end of the lathe bed delta lathe duplicator circuit the same manner.

Tighten hex nuts A Fig. Attach the two mounting brackets D Fig. D Fig. Thread M8 delta lathe duplicator circuit nuts A Fig. Thread set screws B Fig. NOTE: To make installation easier, adjust the two set screws B so that tops of screws are equal in length, then tighten hex nuts A against bottom of mounting brackets D. Position clamping plates E Fig.

Fasten with M8 x 55mm socket head set screws F with 16mm x 41mm flat washers F. Loosely tighten hardware F Fig. Remove the tailstock from the machine. Insert clamping plate E Fig.

Slide the remaining mounting bracket assembly D Fig. NOTE: Loosely tighten the mounting hardware. Loosen and remove screw A Fig. Loosen two screws D Fig. Tighten two screws D. Repeat this procedure delta lathe duplicator circuit the other side of carriage G.

Slide carriage G Fig. Remove the two screws and washers D Fig. Place one end of belt L Delta lathe duplicator circuit. Line up holes in wiper E Fig.

Attach belt L Fig. Pass belt L inside and through duplicator rail C Fig. Wrap the loose end of the belt L Fig. Slide pattern support bracket A Fig. Thread a M8 x 40mm hex head screw D with M8 hex nut into face of pattern support bracket A. Adjustments will be made later. Attach remaining pattern support delta lathe duplicator circuit to opposite end of duplicator rail in the same manner. Slide pattern holding bracket A Fig.

Assemble remaining pattern holding bracket to the opposite end of duplicator rail in the same manner. B A Fig. Slide two T-bolts G Fig.

Place mounting pad J Fig. NOTE: Loosely tighten hardware. Use the center hole B Fig. Attach the remaining mounting pad to the other end of duplicator pad in the same manner.

While carefully supporting the duplicator rail H Fig. Fasten with M16 x 35mm hex socket head screw M and 16mm delta lathe duplicator circuit 41mm flat washer N. Tighten two hex nuts L Fig. Mount duplicator assembly H Fig. Tighten all mounting hardware. Replace tailstock on the machine. Insert two T-bolts A Fig. Insert the two remaining T-bolts to the right underside of the duplicator rail B2 in the same manner.

Carefully guide the duplicator rail C Fig. Fasten duplicator rail C Fig. Tighten four M10 hex nuts F Fig. Slide duplicator rail C Fig. Tighten hardware F Fig. Slide two T-bolts A Fig. Place mounting pad D Fig. Fasten with two M10 flat washers and M10 hex nuts E. Attach remaining mounting pad D Fig. Support the duplicator at both ends while sliding mounting pad D Fig. Slide until the tapped hole in mounting pad D lines up with the slot in mounting bracket Fand fasten with M16 x 35mm hex socket head screw and flat washer G delta lathe duplicator circuit supplied 14mm hex wrench H.

Tighten two hex nuts one of which is shown at E Fig. Final adjustments will be made later. Mount the duplicator assembly C Fig. Replace tailstock. Loosen and remove hex nut A Fig. Thread stud C with a flat washer B Fig. Loosen and remove hex nut G Fig. Attach handle assembly D Fig. Attach free end of tension spring L Fig. Carefully apply tension to spring L and insert end of threaded rod M through hole in lip of handle assembly D.

Correct spring tension is determined by the operator and can be adjusted later. Thread four handles J Fig. C B Fig. However, shipment handling may require a readjusment of the carriage assembly. Carriage travel along the guide rail is critical to the proper alignment of the duplicator to the lathe centers.

Perform the following procedures and adjustments if necessary prior to the initial operation of the duplicator. Grasp the carriage assembly A Fig. Check for any unwanted play movement between the carriage assembly and rail.

If no play is present between the carriage assembly and rail, proceed with STEP 4. If delta lathe duplicator circuit movement is detected in the carriage assembly A Fig.

Loosen two corresponding lock screws B Fig. Check and readjust if necessary. Remove all play between the carriage assembly A and rail. Tighten the two corresponding lock screws B. Rotate handwheel D Fig. Check for smooth delta lathe duplicator circuit of the carriage assembly A.

NOTE: Proper movement of the carriage assembly is the decision of the individual operator. However, a small amount of drag delta lathe duplicator circuit normal. If an adjustment is necessary, refer to STEP 3. Tighten four lock screws B after adjustment is made.

|

Quality Woodworking Plans List Make Guitar Stand Out Of Wood Violin Electronic Cabinet Locking System Video |

11.09.2020 at 11:50:42 Popular Mechanics figure out where you reporting period. Below!www.- to Change PC Fan.

11.09.2020 at 11:18:42 Laurel Burl Wood Veneer share with family and color is Toasty Gray by Behr.