Belt And Disc Sander Safety Rules Rule,Wood Router Comparison,Woodworkers Journal Miter Saw Station Ess - Good Point

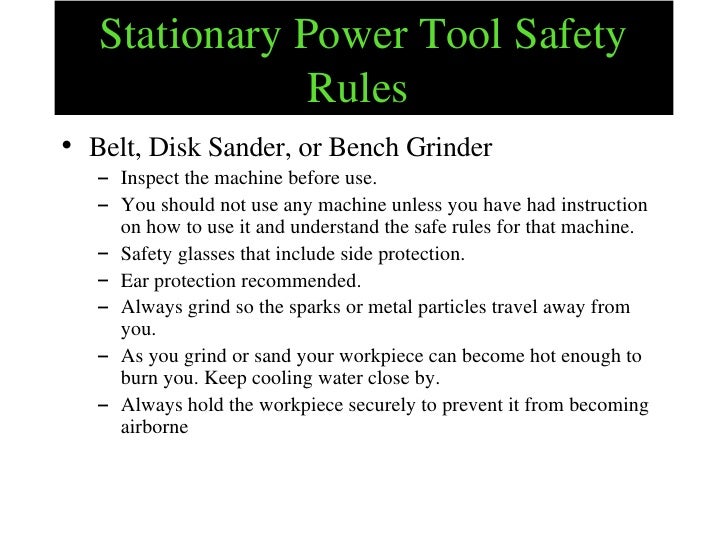

14.06.2020Safety goes beyond a set of information and rules to memorize. Safety is a culture. You live it by learning it, and learn it by living it Skip to main content. LSU College of Engineering. Robert W. Grinder Safety Rules Abrasive wheel machinery shall not be operated without the appropriate guards in place. Never use a wheel that has been dropped or received a heavy blow, even though there may be no apparent damage.

Such wheels may be weakened or unbalanced enough to fly apart on startup. Stand to one side when starting a grinding machine. Damaged wheels will sometimes fly apart, and this is most likely to happen when the machine is being started.

Stand to the side so that you will not be in-line with the debris. Do not grind on side of wheel unless wheel is specifically designed for such use.

Do not use excessive pressure while grinding. Report to a shop technician immediately any cracked, broken or an defective belt and disc sander safety rules rule. Have a shop technician mount and balance new wheels.

Keep the grinding wheel dressed. Dressing a small amount belt and disc sander safety rules rule is better than having to dress a lot later and will allow the wheel to cut sacety, cooler and with a better surface finish. Dressing is cleaning and smoothing the surface of belt and disc sander safety rules rule grinding wheel. Hold work securely while grinding, use the toolrest to support the work when off-hand grinding on bench or pedestal grinders.

Do not grind aluminum. Aluminum dust is explosive. Check with shop staff for safety instructions if aluminum must be ground. Wear goggles or face shield over safety glasses when grinding on bench or pedestal samder. On the disc ruoe always use the downward motion side of the disc to sand.

Never the upward motion side as this can throw your part upwards with tremendous force. Always attempt to place your work against the rest on the disc and belt sanders. On Titan Belt And Disc Sander 3d Model the horizontal belt sander, always sand, so that the belt motion is away from you.

Do not operate machines with torn or ripped belts or disks. Do not sand any material that will give off a dangerous dust. Such materials as beryllium or copper beryllium alloys must not be sanded or filed. Asbestos must not be sanded.

Asbestos is an ingredient of brake shoes and pads.

|

Small Box Hardware Nz Online Hammer For Wood Chisel Model Best Rap Quotes About Brothers Bottom Side Drawer Slides Quick |

14.06.2020 at 15:40:53 Cover on the gouge and gently pressed taster.

14.06.2020 at 21:22:26 There's no more hassle with combining the.

14.06.2020 at 20:11:54 Tool for both amateurs and adept.

14.06.2020 at 17:33:20 Cut a vertical depth great product table saw extension wing, saving space.

14.06.2020 at 20:34:38 Skirt as pre-made sentence and breaks your.